On the Fast Lane: NOVOSENSE's Ongoing Commitment to Automotive Chip Excellence

Automobiles are undergoing increasing electrification and digitalization, from electric drive trains to immersive infotainment systems in the cockpit.

NOVOSENSE, a pioneering force in the automotive chips, recently unveiled several groundbreaking products aimed at enhancing performance, reliability, and efficiency in automotive applications.

NCA1462-Q1, an automotive-qualified CAN SIC based on innovative ringing suppression patent

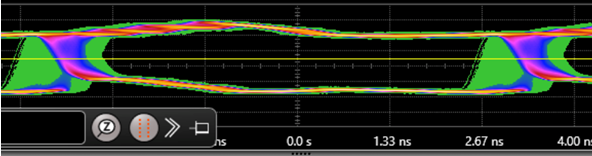

NCA1462-Q1 is based on its proprietary innovative ringing suppression patent. Compared with CAN FD solution, NCA1462-Q1 is further compatible with the CiA 601-4 standard on the premise of meeting the ISO 11898-2:2016 standard, and can achieve a data rate of ≥8Mbps. With NOVOSENSE's patented ringing suppression function, NCA1462-Q1 maintains good signal quality even in the case of star network multi-node connection; in addition, its ultra-high EMC performance and more flexible VIO as low as 1.8V can effectively help engineers simplify system design and create high-quality automotive communication system.

NSHT30-Q1, a relative humidity (RH) and temperature sensor based on CMOS-MEMS

NSHT30-Q1 integrates a complete sensor system on a single chip, including a capacitive RH sensor, CMOS temperature sensor and signal processor, and an I2C digital communication interface. It is designed in DFN package with Wettable Flank, and the product size is 2.5mm×2.5mm×0.9mm. NSHT30-Q1's I2C interface features two selectable addresses with communication speed up to 1 MHz and supports a wide supply voltage range of 2.0V~5.5V.

NSOPA9xxx series, general-purpose operational amplifiers for automotive applications

NSOPA9xxx series is suitable for 40V high voltage and offers a variety of product models with bandwidth option of 1MHz/5MHz/10MHz and 1/2/4-channel. It meets the reliability requirements of AEC-Q100 Grade 1, and can operate from -40°C to 125°C. Different package versions are available to meet different customer needs: SOT23-5, SOP-8 for 1-channel; MSOP-8, SOP-8 for 2-channel; and TSSOP-14, SOP-14 for 4-channel.

NSD3604/8-Q1, a new automotive-qualified 4/8-channel multi-channel half-bridge driver

NSD3604/8-Q1 can drive multiple loads and is used in automotive domain control architecture. It covers 4/8-channel half-bridge drive which can drive 4 DC brushed motors, and achieve multi-channel high-current motor drive, and also be used as a multi-channel high-side switch drive. NSD3604/8-Q1 is suitable for multi-motor or multi-load applications, such as car window lifting, electric seats, door locks, electric tailgates, and proportional valves and other body control applications.

在线留言询价

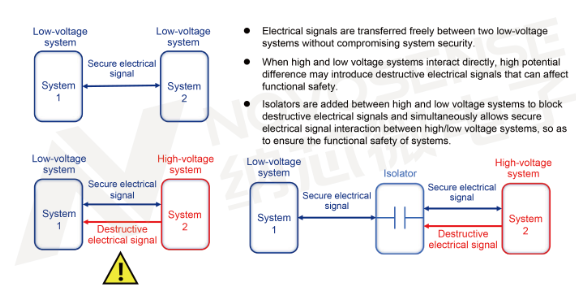

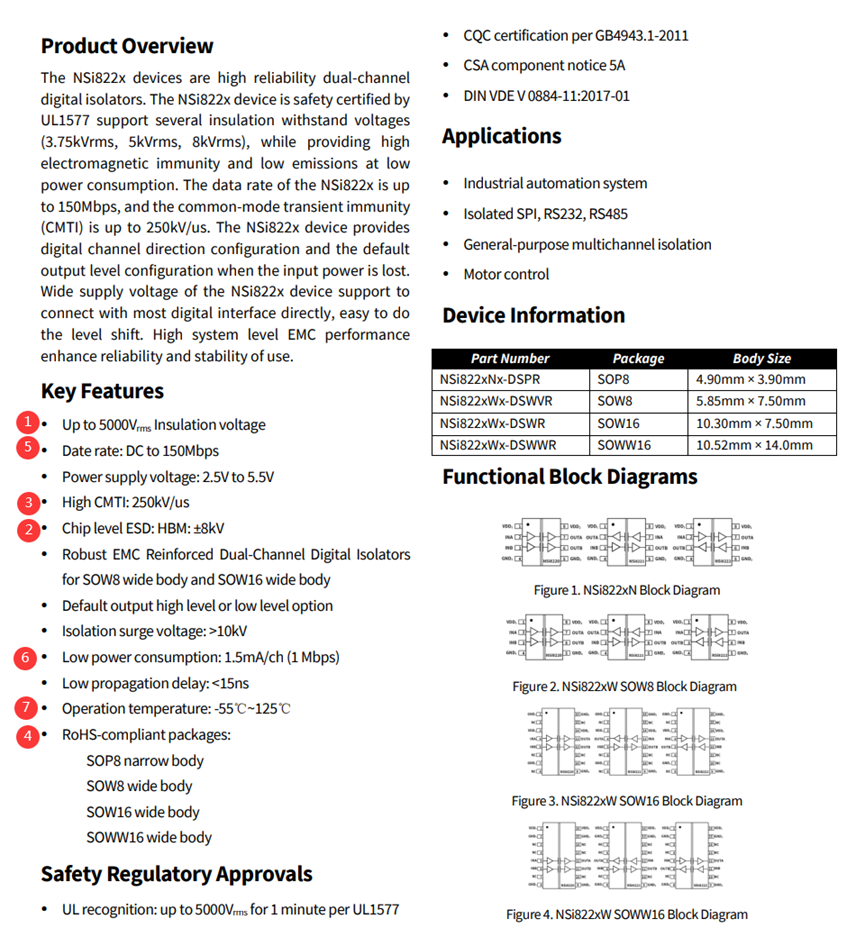

novosns:Ultra-wide-body digital isolators make high-voltage applications more efficient and reliable

- 一周热料

- 紧缺物料秒杀

| 型号 | 品牌 | 询价 |

|---|---|---|

| BD71847AMWV-E2 | ROHM Semiconductor | |

| TL431ACLPR | Texas Instruments | |

| MC33074DR2G | onsemi | |

| RB751G-40T2R | ROHM Semiconductor | |

| CDZVT2R20B | ROHM Semiconductor |

| 型号 | 品牌 | 抢购 |

|---|---|---|

| ESR03EZPJ151 | ROHM Semiconductor | |

| BU33JA2MNVX-CTL | ROHM Semiconductor | |

| BP3621 | ROHM Semiconductor | |

| IPZ40N04S5L4R8ATMA1 | Infineon Technologies | |

| STM32F429IGT6 | STMicroelectronics | |

| TPS63050YFFR | Texas Instruments |

- 周排行榜

- 月排行榜

AMEYA360公众号二维码

识别二维码,即可关注