- Ameya360 Component Supply Platform >

- Trade news >

- Advanced Technology Key to Strong Foundry Revenue per Wafer

Advanced Technology Key to Strong Foundry Revenue per Wafer

Analysis shows more than a 16x difference between the average revenue generated by 0.5µ 200mm wafers ($370) and ≤20nm 300mm wafers ($6,050).

The average revenue generated from processed wafers among the four biggest pure-play foundries (TSMC, GlobalFoundries, UMC, and SMIC) is expected to be $1,138 in 2018, when expressed in 200mm-equivalent wafers, which is essentially flat from $1,136 in 2017, according to a new analysis by IC Insights (Figure 1). The average revenue per wafer among the Big 4 foundries peaked in 2014 at $1,149 and then slowly declined through last year, based on IC Insights’ extensive part-two analysis of the integrated circuit foundry business in the September Updateto The 2018 McClean Report.

Figure 1

TSMC’s average revenue per wafer in 2018 is forecast to be $1,382, which is 36% higher than GlobalFoundries’ $1,014. UMC’s average revenue per wafer in 2018 is expected to be only $715, about half of the projected amount at TSMC this year. Furthermore, TSMC is the only foundry among the Big 4 that is expected to generate higher revenue per wafer (9% more) in 2018 than in 2013. In contrast, GlobalFoundries, UMC, and SMIC’s 2018 revenue per wafer averages are forecast to decline by 1%, 10%, and 16%, respectively, compared to 2013.

Although the average revenue per wafer of the Big 4 foundries is forecast to be $1,138 this year, the amount generated is highly dependent upon the minimum feature size of the IC processing technology. Figure 2 shows the typical 2Q18 revenue per wafer for some of the major technology nodes and wafer sizes produced by pure-play foundries. In 2Q18, there was more than a 16x difference between the 0.5µ 200mm revenue per wafer ($370) and the ≤20nm 300mm revenue per wafer ($6,050). Even when using revenue per square inch, the difference is dramatic ($7.41 for the 0.5µ technology versus $53.86 for the ≤20nm technology). Since TSMC gets such a large percentage of its sales from ≤45nm production, its revenue per wafer is expected to increase by a compound annual growth rate (CAGR) of 2% from 2013 through 2018 as compared to a -2% CAGR for the total revenue per wafer average of GlobalFoundries, UMC, and SMIC during this same timeperiod.

Figure 2

There will probably be only three foundries able to offer high-volume leading-edge production over the next five years (i.e., TSMC, Samsung, and Intel). IC Insights believes these companies are likely to be fierce competitors among themselves—especially TSMC and Samsung—and as a result, pricing will likely be under pressure through 2022.

Online messageinquiry

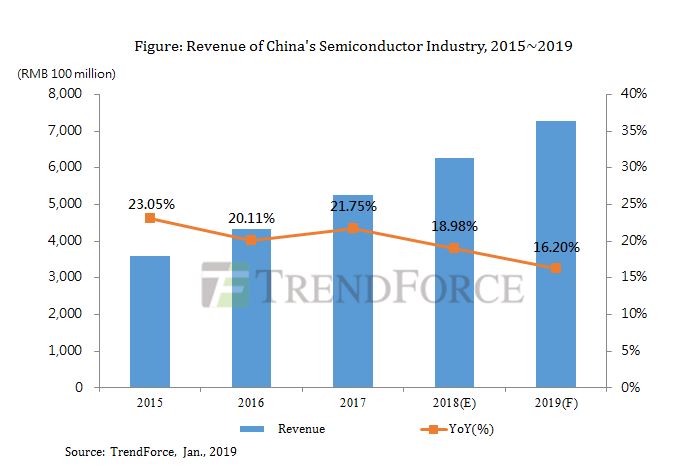

Revenue Growth in China's Semiconductor Industry Would Slow Down to 16.2% in 2019 due to Pessimistic

- Week of hot material

- Material in short supply seckilling

| model | brand | Quote |

|---|---|---|

| RB751G-40T2R | ROHM Semiconductor | |

| TL431ACLPR | Texas Instruments | |

| CDZVT2R20B | ROHM Semiconductor | |

| MC33074DR2G | onsemi | |

| BD71847AMWV-E2 | ROHM Semiconductor |

| model | brand | To snap up |

|---|---|---|

| IPZ40N04S5L4R8ATMA1 | Infineon Technologies | |

| ESR03EZPJ151 | ROHM Semiconductor | |

| BU33JA2MNVX-CTL | ROHM Semiconductor | |

| STM32F429IGT6 | STMicroelectronics | |

| TPS63050YFFR | Texas Instruments | |

| BP3621 | ROHM Semiconductor |

- Week of ranking

- Month ranking

Qr code of ameya360 official account

Identify TWO-DIMENSIONAL code, you can pay attention to

Please enter the verification code in the image below: