- Ameya360 Component Supply Platform >

- Trade news >

- ZEISS:Reliable evaluation software for inline and atline X-ray inspection

ZEISS:Reliable evaluation software for inline and atline X-ray inspection

ZEISSAutomated Defect Detection (ZADD) software allows even the smallest defects in components to be detected reliably, quickly and automatically, so that even small and fuzzy defects to be evaluated. In doing so, the Automated Defect Detection (ADD) software, also called Automated Defect Recognition (ADR) software, can be used not only for injection molded parts, but also for batteries and printed components (MED/AM).

ZEISS offers everything from a single source: with the complete ZEISS X-ray portfolio, you can use artificial intelligence (AI) in 3D computed tomography (CT) and 2D X-ray technology both inline and atline. ZEISS Automated Defect Detection software is compatible with all ZEISS computed tomography systems.]

Reliably detect defects in components

During the complex manufacturing process of components, different defects can occur. Especially inside, they are invisible to the naked eye and can have a major impact on the stability and functionality of the component. Artificial intelligence combined with industrial computed tomography or 2D X-ray technology makes these hidden problem areas visible, analyzes them and detects them at an early stage. The ZEISS Automated Defect Detection software specializes in the detection of different defects, so that defects can be detected quickly and reliably even in poor image quality with many artifacts.

Inline defect analysis in just 60 seconds

In order to be able to sort out defective components at an early stage in a value chain, the 3D data must be evaluated reliably and quickly during an inline inspection. In just 60 seconds, the ZEISS Automated Defect Detection analysis software reliably examines 4 billion voxels (3D pixels) for defects that are only a few voxels in size. Components with critical defects are thus accurately sorted out or, if possible, subjected to rework. Good parts, on the other hand, pass through the further machining process unhindered. The result: a lower reject rate and high component quality. In this way, you achieve a constant increase in efficiency and maximum process reliability with AI in CT.

Reliable evaluation

If the ZEISS Automated Defect Detection software detects a defect, the software evaluates it in terms of position, shape, size and type. For example, if pores are close to a surface that will be machined in the further process, they may pose a greater risk than elsewhere inside the component. The software is able to predict whether the defect may cause problems in subsequent machining steps. The component is then automatically rejected at an early stage. This saves you time and money. In addition, you can define in the ZEISS Automated Defect Detection software under which criteria a defect still meets the quality standards and when it is classified as critical. With ZEISS Automated Defect Detection, you get a solution that is tailored precisely to your requirements.

Clear reporting

If the ZEISS Automated Defect Detection software finds a critical defect in inline operation, it creates a report using the ZEISS PiWeb data management software. This gives you the opportunity to view and evaluate defects again afterwards in a 3D view. If your manual inspection leads you to the conclusion that the defect was caused by sand residue, for example, you can easily remove this source of defect and avoid unnecessary scrap. This results in high cost savings. The software also enables results to be displayed in tabular form and output in common formats such as csv.

Online messageinquiry

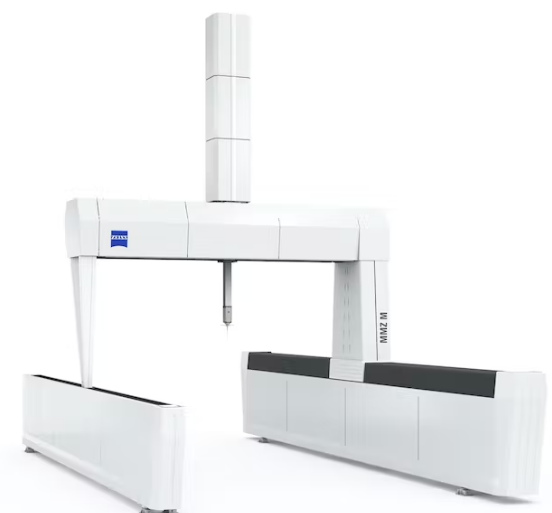

AMEYA360:ZEISS Xradia CrystalCT

ZEISS:Industrial 3D Scanning Technology

- Week of hot material

- Material in short supply seckilling

| model | brand | Quote |

|---|---|---|

| MC33074DR2G | onsemi | |

| CDZVT2R20B | ROHM Semiconductor | |

| BD71847AMWV-E2 | ROHM Semiconductor | |

| RB751G-40T2R | ROHM Semiconductor | |

| TL431ACLPR | Texas Instruments |

| model | brand | To snap up |

|---|---|---|

| BU33JA2MNVX-CTL | ROHM Semiconductor | |

| STM32F429IGT6 | STMicroelectronics | |

| TPS63050YFFR | Texas Instruments | |

| IPZ40N04S5L4R8ATMA1 | Infineon Technologies | |

| BP3621 | ROHM Semiconductor | |

| ESR03EZPJ151 | ROHM Semiconductor |

- Week of ranking

- Month ranking

Qr code of ameya360 official account

Identify TWO-DIMENSIONAL code, you can pay attention to

Please enter the verification code in the image below: