- Ameya360 Component Supply Platform >

- Trade news >

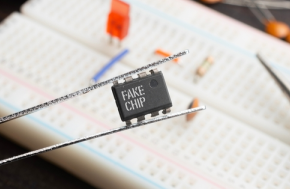

- AMEYA360:Distributors Boost Testing as Counterfeit Risks Rise

AMEYA360:Distributors Boost Testing as Counterfeit Risks Rise

The risk of procuring counterfeit components always increases when electronic devices are in tight supply. Between 2021 and 2022 – the height of the unprecedented semiconductor shortage – reports of suspect or nonconforming parts increased by 35 percent, according to the ERAI, which collects data on counterfeits.

Notably, global semiconductor sales were flat during that period.

The reality is counterfeit components are omnipresent in the electronics supply chain. One of the most common scams is re-marking (or “blacktopping”) common or even sub-par components as pricier, high-reliability devices. Although the parts are authentic, they could fail in high-stress environments. Analog ICs, programmable logic ICs and microprocessor ICs are the most frequent targets of counterfeiters.

Testing for counterfeit parts has been standard operating procedure at Sourceability since its founding in 2015

Jens Gamperl, Sourceability

Demand for component testing has increased significantly during the chip shortage despite costs — as much as $2,000 — and delays that are incurred during the process. Testing is often outsourced and can damage sample devices. But for a portion of the distribution market, test capabilities distinguish them as trusted sources of supply.

Independent, non-franchised distributors source from the open market where component makers, OEMs, EMS providers and other organizations sell excess inventory. Components that can’t be traced back to a factory; arrive in opened or damaged packaging; or are heavily discounted could be counterfeit. Stringent quality control (QC) has become paramount for top-tier independents.

However, testing has created a backlog of orders as shortages stretch on. Last year, independent distributor Fusion Worldwide acquired a test house based in Singapore. Another independent, Sourceability, has established test labs in each of its 4 global warehouses. From the company’s founding in 2015 testing has been standard operating procedure, according to Jens Gamperl, CEO and founder of Sourceability.

“The tide is turning for independent distributors, which often get confused with brokers,” he noted. “They are clearly two different things.”

Brokers are opportunistic organizations that buy low and sell high during supply disruptions and have been known to set up shop, take orders; and then disappear after payment. They are a common source of counterfeit parts. ERAI saw suspect capacitor reports spike over a 5-year period that included a severe shortage.

Trust but verify

Based on sources of components Sourceability has a 3-level verification process. One of the biggest challenges in the open market, Gamperl said, are parts that are authentic but have been re-marked as something else.

“There are different sources of counterfeits,” Gamperl explained. “What what we see once in a while is that a manufacturer decides that product is not on their quality level, and they send it to a destruction facility, and on the way the shipment gets lost.”

Even products that can be traced back to manufacturers (level 1) are verified by brand, part number, packaging, date code and dimensions. “We have a large database of known parts, so it’s relatively easy to test a component’s dimensions,” Gamperl said.

Sourceability maintains data on components, suppliers and customers it has dealt with at one time or another. Customers sometimes ask distributors to procure parts on their behalf. “If we haven’t bought one part from a supplier in, say, 10 years, there’s usually a good reason,” Gamperl said.

Level 2 testing is done on components bought from authorized distributors, which source directly from component factories. Sourceability checks for open packs, resealed packaging, cut tape or 3rd party packaging. Acceptable quality level sample inspection is done based on the quantity received, using various microscopy options to validate conformance.

The risk of procuring counterfeit components always increases when electronic devices are in short supply“Where we have no traceability, we always do a level 3 inspection,” Gamperl said. These devices are sourced from independent distributors, contract manufacturers/other excess channels and brokers. Markings on components are tested for permanence – a destructive solvent test (heated solvent) is used to detect epoxy-based blacktopping.

Devices are also analyzed through x-ray florescence (XRF), are tested for solderability and undergo chemical decapsulation.

“This usually means we take the packaging off and go down to the die and view the wiring through x-rays,” Gamperl said. By removing external packaging on a semiconductor and exposing the semiconductor wafer or die, microscopic inspection of brand marks, trade marks, and laser die etching can be used to determine authenticity. These tests damage samples, but some customers in the automotive or defense industries, for example, will not accept shipments without seeing test results beforehand.

Equipment or facility investment has become a cost of doing business for many independents. Sourceability’s labs use:

High Power Microscopy Capabilities Keyence VHX5000, VHX7000, Olympus DSX1000

Keyence IM-7020 Instant Measuring Equipment

Heated Chemical Testing (HTC)

Creative Electron TruView? Prime X-Ray Inspection System

Glenbrook Technologies JEWEL BOX 70T

RoHS Testing with X-Ray Fluorescence (XRF) Equipment Olympus : Xpert Model

RoHS Testing with X-Ray Fluorescence (XRF) Equipment Fischer Technology-XDAL-237 SDD

NISENE Jet-Etch Pro Acid Decapsulation System

RPS Prelude Dip and Look Solderability Test System

RPS Cadence Steam Aging System

Memmert JEDEC J-STD-033 and UF260 Universal Drying Ovens

Sometimes, functionality testing is the only way to spot a counterfeit part. Counterfeits are getting more sophisticated, Gamperl notes, and resellers are always a step behind. But out of 50,000 recent shipments, Sourceability caught 120 counterfeits. “That’s small portion, even if counterfeiting has increased,” he added.

Online messageinquiry

- Week of hot material

- Material in short supply seckilling

| model | brand | Quote |

|---|---|---|

| TL431ACLPR | Texas Instruments | |

| CDZVT2R20B | ROHM Semiconductor | |

| BD71847AMWV-E2 | ROHM Semiconductor | |

| RB751G-40T2R | ROHM Semiconductor | |

| MC33074DR2G | onsemi |

| model | brand | To snap up |

|---|---|---|

| BP3621 | ROHM Semiconductor | |

| ESR03EZPJ151 | ROHM Semiconductor | |

| IPZ40N04S5L4R8ATMA1 | Infineon Technologies | |

| TPS63050YFFR | Texas Instruments | |

| STM32F429IGT6 | STMicroelectronics | |

| BU33JA2MNVX-CTL | ROHM Semiconductor |

- Week of ranking

- Month ranking

Qr code of ameya360 official account

Identify TWO-DIMENSIONAL code, you can pay attention to

Please enter the verification code in the image below: