What is a multi-layer ceramic capacitor

Multi-layer ceramic capacitor (MLCC) is a type of ceramic capacitors. It is characterized by small size, large capacity, affordable price, good stability, low loss rate during high-frequency use, and suitable for mass production. As an important part of passive components, multilayer ceramic capacitors have a wide range of applications in consumer electronics, automotive electronics and other fields.

In recent years, the consumer electronics, communication equipment and automotive industries have boomed, especially the demand for mobile phones and electric vehicles and sales growth, driving strong demand. At present, consumer electronics, automotive electronics and other industries will continue to develop rapidly, and the prospects of multilayer ceramic capacitors are very promising.

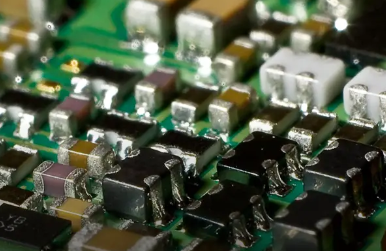

What is a multi-layer ceramic capacitorMulti-layer ceramic capacitor (MLCC) is one of PCB capacitors using multilayer ceramic sheets as an intermediate medium and an electronic component widely utilized in electronic circuits for its capability to accumulate and discharge electrical energy. It consists of several layers of ceramic material, usually composed of barium titanate or other ceramic materials, that are stacked on top of each other with metal electrodes sandwiched between them.

Due to their compactness, dependability, low inductance, and ESR (Equivalent Series Resistance) properties, Multi-layer ceramic capacitors are popular and ideal for high-frequency applications. They are commonly used in electronic devices such as smartphones, computers, and automotive electronics.

What are the different types of MLCC capacitors

Multi-layer ceramic capacitor comes in different types, classified based on their intended application, construction, and material composition. These types include General-Purpose MLCCs, High Voltage MLCCs, High-Q MLCCs, Automotive Grade MLCCs, Soft Termination MLCCs, and Safety Certified MLCCs.

● General-Purpose MLCCs are the most commonly used type, constructed with a ceramic dielectric material, and are available in varying capacitance values, voltage ratings, and sizes.

● High Voltage MLCCs are designed for high-voltage applications, while High-Q MLCCs are meant for high-frequency applications requiring low loss and high stability, using high dielectric constant ceramic material.

● Automotive Grade MLCCs withstand harsh environmental conditions in automobile applications.

●Soft Termination MLCCs feature flexible termination structures to minimize the risk of capacitor cracking during thermal and mechanical stress.

● Safety Certified MLCCs are tested and certified to meet safety standards and are used in safety-critical applications.

Choosing the appropriate multi-layer ceramic capacitor type for an application will depend on factors like operating frequency, voltage, capacitance requirements, environmental conditions, and other considerations.

What is the advantage and disadvantage of the MLCC capacitormulti-layer ceramic capacitor has several advantages and disadvantages, which are important to consider when selecting a capacitor for a particular application.

★ Advantages of multi-layer ceramic capacitor include:

● High Capacitance: multi-layer ceramic capacitor has a high capacitance density, which allows them to store large amounts of electrical charge in a small package.

● Low ESR: multi-layer ceramic capacitor has a low Equivalent Series Resistance (ESR), which means that they can respond quickly to changes in current and voltage.

● High-Frequency Performance: multi-layer ceramic capacitor has a high self-resonant frequency, which allows them to operate at high frequencies without degrading performance.

● High Reliability: multi-layer ceramic capacitor is highly reliable, with a low failure rate and a long operating life.

★ Disadvantages of multi-layer ceramic capacitor include:

● Limited Voltage Range: Multi-layer ceramic capacitors are typically limited to relatively low voltage ratings, and are not suitable for high-voltage applications.

● Temperature Dependence: The capacitance of multi-layer ceramic capacitor can vary significantly with changes in temperature, which can affect their performance.

● Piezoelectric Effects: MLCC capacitors are made of ceramic materials, which can exhibit piezoelectric effects under certain conditions. This can cause voltage spikes or noise in some applications.

● Capacitance Variations: The actual capacitance of an MLCC capacitor can vary from its rated value, due to manufacturing tolerances or changes in temperature, which can affect its performance.

Overall, MLCC capacitors are widely used in many electronic applications due to their high capacitance density, low ESR, and high-frequency performance. However, they may not be suitable for all applications, and care must be taken to select the appropriate type and voltage rating for a particular application.

How are multilayer ceramic capacitors made

Multilayer ceramic capacitors are made using a process called tape casting, which involves the following steps:

● Ceramic Powder Preparation: The ceramic powder used to make the multi-layer ceramic capacitor is prepared by mixing together different materials, such as barium titanate, with binders and solvents. This mixture is then ground into a fine powder.

● Tape Casting: The ceramic powder is then mixed with a solvent to create a slurry, which is spread onto a flat surface to form a thin layer. This layer is then cut into rectangular sheets, which will become the capacitor layers.

● Electrode Deposition: Metal electrodes, typically made of silver or palladium, are deposited onto the ceramic sheets using a screen printing process. The electrodes are patterned to form the desired capacitor shape.

● Layer Stacking: The ceramic sheets with the metal electrodes are then stacked on top of each other, with a layer of insulating material, such as glass or ceramic, in between each layer.

● Pressing and Sintering: The stacked layers are then pressed together and sintered at high temperatures, typically around 1200°C, to fuse the layers together and form a solid ceramic block.

● Terminal Attachment: The capacitor leads or terminals are attached to the block using a conductive adhesive or soldering process.

● Testing and Inspection: The finished multi-layer ceramic capacitor is then tested to ensure that they meet the required specifications for capacitance, voltage rating, and other parameters. They are also inspected for any visual defects or imperfections.

Once the multi-layer ceramic capacitors have been manufactured, they can be packaged and shipped to customers for use in electronic circuits.

How do multilayer ceramic capacitors work

Multilayer ceramic capacitors function by storing electrical charge between two conductive plates separated by a dielectric material. In multi-layer ceramic capacitor, the conductive plates are metal electrodes such as silver or palladium, and the dielectric material is ceramic.

When a voltage is applied to the electrodes, an electric field forms in the dielectric material, which polarizes the electrons, creating an electrical charge on the electrode’s surface. The capacitance of an multi-layer ceramic capacitor depends on the surface area of the electrodes, the distance between them, and the dielectric constant of the material. The higher the dielectric constant, the easier the material polarizes, with ceramics having a higher dielectric constant than other dielectric materials.

Multi-layer ceramic capacitor is versatile and used in various electronic circuits, including filters, oscillators, and power supplies, to store and release electrical charge. Their low Equivalent Series Resistance (ESR) and high self-resonant frequency make them suitable for high-frequency circuits, improving performance and reducing losses.

Do multilayer ceramic capacitors have polarityMulti-layer ceramic capacitor can be classified into two types: polar and non-polar.

Non-polar MLCCs are symmetrical in construction and can be connected in either direction without any polarity concerns.

In contrast, polar MLCCs are designed asymmetrically and must be connected in a specific orientation to function correctly. The positive and negative terminals of polar MLCCs are indicated by markings such as stripes, dots, letters, or color codes. It is crucial to connect polar Multi-layer ceramic capacitors properly as reversing the polarity can lead to capacitor failure or even an explosion. Soldering of polar MLCCs should also be done carefully to prevent overheating or damage.

What is the raw material for MLCC

The raw materials used to make multilayer ceramic capacitors include:

● Ceramic powder

● Metal powder

● Binder

● Solvent

● Glass or ceramic insulators

These raw materials are carefully selected and blended to create a mixture that has the desired properties for the specific multi-layer ceramic capacitor product, such as capacitance, voltage rating, and temperature stability. The manufacturing process involves several steps, including mixing, casting, electrode deposition, layer stacking, pressing, and sintering, which transforms the raw materials into a finished multi-layer ceramic capacitor product.

What is the voltage rating of a multilayer ceramic capacitor

Multilayer ceramic capacitor has different voltage ratings, depending on the specific application and product. The voltage rating can vary from a few volts to several thousand volts. For instance, low-voltage MLCCs with ratings of 6-50 volts are typically utilized in consumer electronics, such as mobile phones and computers, for decoupling and signal filtering.

On the other hand, medium-voltage multi-layer ceramic capacitors with ratings of 100-500 volts are commonly used in applications such as lighting, motor control, and power supplies. High-voltage MLCCs with ratings of 1,000-5,000 volts are used in high-power applications, including industrial equipment, renewable energy systems, and electric vehicles.

The voltage rating of an MLCC denotes the maximum voltage that the capacitor can withstand without failing or breaking down. It is important to select an MLCC with a voltage rating that matches the requirements of the application to ensure safe and reliable operation.

在线留言询价

- 一周热料

- 紧缺物料秒杀

| 型号 | 品牌 | 询价 |

|---|---|---|

| CDZVT2R20B | ROHM Semiconductor | |

| BD71847AMWV-E2 | ROHM Semiconductor | |

| RB751G-40T2R | ROHM Semiconductor | |

| TL431ACLPR | Texas Instruments | |

| MC33074DR2G | onsemi |

| 型号 | 品牌 | 抢购 |

|---|---|---|

| BU33JA2MNVX-CTL | ROHM Semiconductor | |

| ESR03EZPJ151 | ROHM Semiconductor | |

| IPZ40N04S5L4R8ATMA1 | Infineon Technologies | |

| STM32F429IGT6 | STMicroelectronics | |

| TPS63050YFFR | Texas Instruments | |

| BP3621 | ROHM Semiconductor |

- 周排行榜

- 月排行榜

AMEYA360公众号二维码

识别二维码,即可关注

请输入下方图片中的验证码: