Nidec CORPORATION:EV Traction Motor System E-Axle

The product that combines the Nidec Group’s technologies to work as an EV’s “heart”

- Nidec leads the world’s vehicle electrification with its compact and light products, component integration capability, and speedy development.

- E-Axle contributes to freeing up designs, improving running performance, power and energy efficiency, noise reduction, and everything else about EVs.

As the use of electric vehicles (EVs) hybrid cars increases, so do the needs for traction motors. Replacing an engine to serve as the “heart” of a car, the traction motor is required to have an excellent torque characteristic (which influences the car’s performance), be efficient to make the vehicle run long, be quite, compact, and light, have a wonderful reliability, and be easy to maintain, among so many other requirements, while the demands for the motors’ quality are increasing rapidly as well.

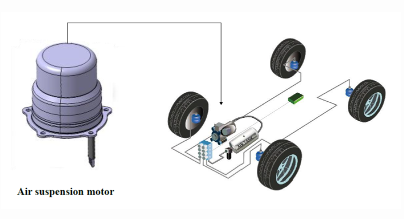

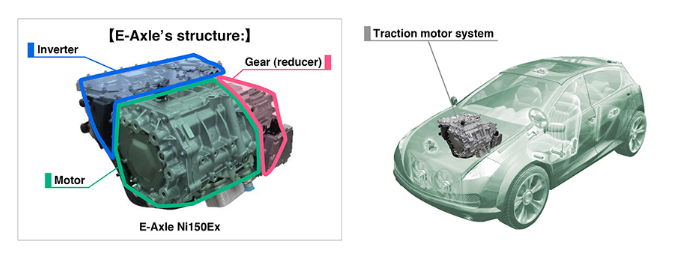

Moving a vehicle requires an inverter and a reducer, in addition to a motor. Nidec developed E-Axle, an EV traction motor system that combines these three components, and started mass-producing it in April 2019.

The E-Axle, which combines a motor, an inverter, and a reducer, can be installed in a vehicle, and, when supplied with electricity, it does everything from generating rotating torque from the drive shaft connected to tires, to driving the vehicle. The competition to develop EVs is extremely harsh, and it requires speed. By adopting Nidec’s E-Axle, car manufacturers can develop their EVs in a very short period of time.

Using a unique oil cooling system to make an overwhelmingly compact and light unit

The 150kW output type of Nidec’s E-Axle series is 3900 N·m, and weighs only 87kg. This compact and light product far surpasses those of other companies in terms of power density. This product was made possible thanks to the wide range of product development knowhow that Nidec has long nurtured in the IT field, where we consecutively created the world’s smallest-class motors by using technologies to make ultra-small and -thin products.

In addition, a new cooling method was adopted for Nidec’s E-Axle. Among all traction motors, cooling-type ones require a large space due to their water jacket and other components, which make the motors large and heavy. To avert this issue, Nidec’s E-Axle uses an oil cooling structure, which pours cooling oil directly to sections that require cooling. Thanks to the motor’s two-way oil cooling structure (which comprises a flow cooling system to cool the motor by spraying oil cooled by an oil cooler from the motor’s top section; and the splash cooling system, which cools winding wires’ ends by spurting oil strongly from a rotating motor shaft by centrifugal force), which cools the motor from both the inside and the outside, Nidec successfully developed an astonishingly compact traction motor while maximizing its cooling efficiency.

Improving a motor’s efficiency requires densifying its stator core’s winding wires, but doing so will result in a declined productivity in the coil winding process. This is why Nidec adopted a new, cassette inserter method (which inserts “cassettes” of winding wires into motors) to achieve a high productivity and a high wire-winding performance.

Accelerating the pace of building a mass-production system to become the world’s leading EV traction motor manufacturer

The development of these technologies and methods enabled Nidec’s E-Axle to be adopted into six models in merely a year after its mass-production started, and has been installed in approximately 100,000 vehicles as of December 2020. The E-Axle’s compact and light-weight features enabled car designs to be created more freely, making EVs highly mobile, powerful, power-efficient, and low-noise. E-Axle-installed models are highly popular in China, the country leading the world in spreading the use of EVs. The E-Axle is highly evaluated by people other than Nidec’s customers as well: It was given the top Nikkei Shimbun award in the “2019 Nikkei Brilliant Products and Services Awards” event hosted by Nikkei Inc.

Nidec’s E-Axle received this award based on a comprehensive evaluation of this product in the areas of (i) technological development, (ii) price-effectiveness, (iii) contribution to the company’s performance, (iv) growth potential, (v) uniqueness, and (vi) the impact to industry and society.

Just like engines’ displacements vary, the E-Axle has a wide line up to cover almost all vehicle segments in the world, from compact vehicles to large SUVs. Nidec is expecting to mass-produce five types of standard E-Axle products by 2023 (See the related contents at the end of the page). We are able to develop and mass-produce our products this fast because: Nidec can produce E-Axle’s main components in-house; the company has the product development knowhow from the IT and appliance industries and a corporate culture of fast product development; we have a large number of well-versed people from car manufacturers and tier-1 suppliers; and Nidec has concentrated its internal resources into this business with a strong determination to be the world’s leading EV traction motor manufacturer.

The lineup of Nidec’s traction motor system, E-Axle

Going forward, more people will start driving EVs than they are now, and according to our plan, Nidec will have produced more than 10 million E-Axle units by 2030. Regarding 2025 as the “turning point of the EV,” Nidec is now accelerating its pace of R&D to build traction motor mass-production systems globally, to secure a 40 – 45% global market share in the traction motor business in 2030.

在线留言询价

- 一周热料

- 紧缺物料秒杀

| 型号 | 品牌 | 询价 |

|---|---|---|

| TL431ACLPR | Texas Instruments | |

| BD71847AMWV-E2 | ROHM Semiconductor | |

| RB751G-40T2R | ROHM Semiconductor | |

| CDZVT2R20B | ROHM Semiconductor | |

| MC33074DR2G | onsemi |

| 型号 | 品牌 | 抢购 |

|---|---|---|

| IPZ40N04S5L4R8ATMA1 | Infineon Technologies | |

| STM32F429IGT6 | STMicroelectronics | |

| TPS63050YFFR | Texas Instruments | |

| BP3621 | ROHM Semiconductor | |

| BU33JA2MNVX-CTL | ROHM Semiconductor | |

| ESR03EZPJ151 | ROHM Semiconductor |

- 周排行榜

- 月排行榜

AMEYA360公众号二维码

识别二维码,即可关注

请输入下方图片中的验证码: