What is “component placement” in PCB?

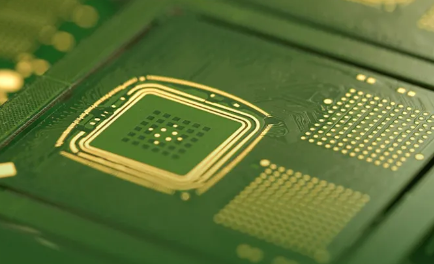

Component placement is a critical step in the PCB assembly process where electronic components are precisely positioned and soldered onto the printed circuit board (PCB). This phase plays a crucial role in ensuring the functionality, reliability, and performance of the final electronic device. Let’s delve into the details of component placement in PCB assembly.

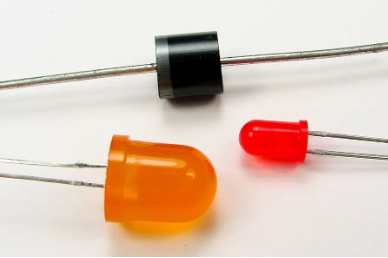

How many electronic components are there?1. Surface Mount Devices (SMDs):

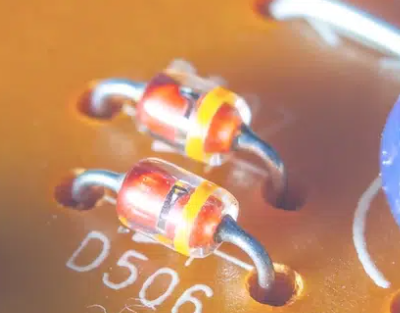

– Passive Components: Resistors, capacitors, inductors.

– Active Components: Integrated circuits (ICs), transistors, diodes.

2. Through-Hole Components:

– Components with leads that pass through holes drilled in the PCB.

What is the component placement process?1. Design for Assembly (DFA)

Before physical assembly begins, the PCB layout and design must consider DFA principles:

– Component Orientation: Optimizing orientation for ease of assembly and efficient routing of traces.

– Clearance and Spacing: Ensuring adequate space for soldering and avoiding interference between components.

– Accessibility: Facilitating automated or manual assembly processes.

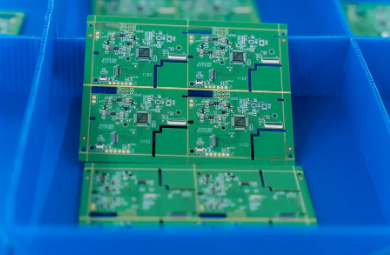

2. Automated Component Placement

Modern PCB assembly typically involves automated pick-and-place machines:

– Vision Systems: Cameras identify fiducial markers or component outlines on the PCB to align and place components accurately.

– Component Feeding: Components are loaded into feeders, which supply them to the pick-and-place machine.

– Pick-and-Place Process: The machine picks components from the feeder using vacuum nozzles, aligns them precisely over corresponding pads on the PCB, and places them gently using controlled motion.

3. Manual Component Placement

For specialized components or low-volume production, manual placement may be used:

– Skill and Precision: Technicians use hand tools like tweezers and magnifiers to place components accurately.

– Prototype Builds: Initial prototypes or small batches may benefit from manual placement for flexibility and customization.

What should be considered when placing components in PCB?Component placement is more than just arranging components on a board; it involves strategic decisions that impact the overall functionality and quality of the PCB. Proper placement not only ensures that the circuit operates correctly but also affects signal integrity, thermal management, and ease of assembly. Here are some crucial aspects to consider:

1. Design for Signal Integrity

Signal integrity is crucial for the proper operation of high-speed digital circuits and sensitive analog circuits. To maintain signal integrity:

– Minimize Trace Length: Place critical components closer together to minimize trace lengths, reducing signal delay and electromagnetic interference (EMI).

– Signal Paths: Follow a logical signal flow from input to output, avoiding crossing high-speed signals with noisy or high-current traces.

– Grounding: Ensure a solid ground plane and place components that require low impedance connections to ground strategically to minimize noise and ground loops.

2. Thermal Management

Certain components, such as power transistors or voltage regulators, generate heat during operation. Efficient thermal management is essential to prevent overheating and ensure reliability:

– Heat Sinks: Provide adequate space and mounting locations for heat sinks or thermal pads.

– Airflow: Arrange components to allow natural or forced airflow across heat-generating components.

– Isolation: Keep heat-sensitive components away from those generating significant heat to prevent thermal damage.

3. Manufacturability and Assembly

Designing for manufacturability involves ensuring that the PCB can be efficiently assembled with minimal errors and rework:

– Component Accessibility: Ensure components are placed such that they can be easily soldered by hand or by automated pick-and-place machines.

– Orientation: Align components consistently for ease of assembly and to avoid errors during soldering.

– Clearance and Spacing: Adhere to manufacturing guidelines for minimum clearance between components, ensuring soldering and inspection can be done without issues.

4. Electromagnetic Compatibility (EMC)

PCB layout plays a crucial role in achieving EMC compliance by reducing EMI emissions and susceptibility:

– Component Arrangement: Position sensitive components and traces to minimize loop areas and coupling.

– Shielding: Group and shield sensitive components from noise sources such as high-current paths or switching circuits.

– Grounding and Routing: Properly route and ground signal return paths to reduce loop areas and impedance discontinuities.

Best Practices for Component Placement– Start with Critical Components: Begin by placing critical components such as microcontrollers, connectors, and high-frequency components based on their functional and spatial requirements.

– Use Design Tools: Leverage PCB design software with simulation capabilities to visualize signal paths, analyze thermal performance, and optimize placement before fabrication.

– Iterative Refinement: Iterate the placement based on simulation results, design reviews, and practical considerations to achieve the best balance of performance and manufacturability.

– Documentation: Clearly label components with reference designators and polarity markings on the silkscreen layer. Maintain an updated BOM (Bill of Materials) to ensure accurate procurement and assembly.

ConclusionComponent placement in PCB assembly is a pivotal stage where careful planning, advanced technology, and skilled craftsmanship converge to create reliable electronic devices. By adhering to DFA principles, leveraging automation, and considering thermal and signal integrity factors, manufacturers can achieve efficient, high-quality assembly that meets the demands of today’s electronics industry. As technology advances, component placement continues to evolve, driving innovation and pushing the boundaries of what’s possible in electronic design and manufacturing.

在线留言询价

15 Common PCB Circuit Effects

- 一周热料

- 紧缺物料秒杀

| 型号 | 品牌 | 询价 |

|---|---|---|

| BD71847AMWV-E2 | ROHM Semiconductor | |

| MC33074DR2G | onsemi | |

| TL431ACLPR | Texas Instruments | |

| CDZVT2R20B | ROHM Semiconductor | |

| RB751G-40T2R | ROHM Semiconductor |

| 型号 | 品牌 | 抢购 |

|---|---|---|

| ESR03EZPJ151 | ROHM Semiconductor | |

| IPZ40N04S5L4R8ATMA1 | Infineon Technologies | |

| TPS63050YFFR | Texas Instruments | |

| BP3621 | ROHM Semiconductor | |

| STM32F429IGT6 | STMicroelectronics | |

| BU33JA2MNVX-CTL | ROHM Semiconductor |

- 周排行榜

- 月排行榜

AMEYA360公众号二维码

识别二维码,即可关注

请输入下方图片中的验证码: