- Ameya360 Component Supply Platform >

- Trade news >

- 15 Common PCB Circuit Effects

15 Common PCB Circuit Effects

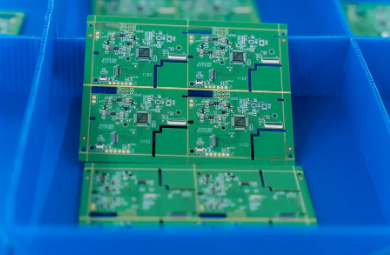

Printed Circuit Boards (PCBs) are the backbone of modern electronics, serving as the foundation for countless devices we rely on daily. However, designing and working with PCBs come with its own set of challenges and nuances. In this guide, we delve into 15 common circuit effects that engineers and enthusiasts encounter when designing and troubleshooting PCBs.

Each effect explored here sheds light on a specific aspect of PCB design, whether it’s related to signal integrity, power distribution, or electromagnetic interference. Through concise explanations and practical examples, we aim to equip readers with a deeper understanding of these effects, enabling them to optimize their PCB designs for performance, reliability, and manufacturability.

Whether you’re a seasoned electronics engineer or a hobbyist diving into the world of PCB design, this guide is designed to serve as a valuable reference, helping you navigate the intricacies of PCB circuits with confidence and expertise.

1. Drawbridging effectIn high-density wiring, when there is not enough space between two lines, a situation may occur where one line hangs over another line, similar to the shape of a suspension bridge.

The drawbridging effect usually occurs in PCB design, especially in cases where a large number of signal lines need to be arranged and space is limited. The drawbridging effect may lead to problems such as signal crosstalk, electromagnetic interference, signal distortion, or delay.

Measures to reduce the drawbridging effect:

Reasonably plan the PCB layout, try to keep the signal lines arranged in a straight line, and avoid situations where lines cross or overlap.

Optimize PCB routing, try to increase the spacing between signal lines as much as possible to avoid the suspension bridge effect caused by too small spaces.

Use layered PCB design to arrange different signal lines on different layers to reduce crossing and interference between lines.

Reduce electromagnetic interference between signal lines by appropriate signal layer and ground layer planning to improve the circuit’s anti-interference ability.

2. Ripple effectIn high-speed circuits, when the signal transmission speed is fast, the signal may undergo ripple deformation when propagating on the PCB, affecting the signal quality, including signal distortion, clock offset, crosstalk, and interference.

Measures to reduce ripple effects:

Optimize PCB layout and routing to minimize the bending, crossing, and branching of signal lines, and maintain the consistency of signal transmission paths.

Adopt appropriate signal line and ground design to reduce crosstalk and interference between signal lines, improving signal transmission quality.

Use signal compensation or pre-emphasis technology to compensate for and enhance the signal, reducing waveform distortion and deformation.

Choose appropriate signal transmission lines and signal processing devices to improve the circuit’s anti-interference ability and transmission speed.

3. Overshoot effectSudden voltage changes that occur during signal transmission may cause excessive voltage shock to components on the circuit board, damaging components or causing circuit failures.

Overshoot effects may be caused by excessively fast rising or falling edges of the signal, or by the instability of the signal transmission line or signal source.

Measures to reduce overshoot effects:

Optimize the design of signal transmission lines to ensure the impedance matching and stability of the signal lines.

Use appropriate power filters and power decoupling capacitors to reduce interference from signal sources.

Adopt signal pre-emphasis technology or signal compensation technology to preprocess or compensate the signal, reducing the occurrence of overshoot effects.

Choose appropriate components and circuit protection devices to improve the circuit’s resistance to overshoot and stability.

4. Resonance effectParameters such as inductance, capacitance, and impedance on the circuit board may cause resonance of the signal at specific frequencies, affecting the stable transmission of the signal. This resonance phenomenon usually occurs at specific frequencies when the frequency of external signals matches the resonant frequency of the circuit, causing resonance effects.

Measures to reduce resonance effects:

Optimize PCB layout and design to avoid situations where the circuit has a resonant frequency close to the excitation frequency.

Use compensation circuits or filters to eliminate or suppress resonance effects.

Choose appropriate damping components or damping materials to reduce the impact of resonance effects.

Adopt appropriate circuit tuning techniques to stabilize the circuit’s frequency response within a specific frequency range.

5. Floating EffectIn high-speed circuits, due to factors such as electromagnetic radiation, signals may float on the surface of conductors or circuit boards, affecting signal transmission and reception.

To reduce the impact of PCB floating effect on circuits, designers can take the following measures:

Measures to Reduce Floating Effect:

Optimize PCB layout and design, plan the routing and spacing of signal lines reasonably, and minimize the impact of electromagnetic radiation on signal transmission.

Use appropriate signal line and ground line designs to ensure impedance matching and stability of signal lines.

Use shielding covers or shielding materials to reduce electromagnetic radiation and interference.

Select suitable PCB materials and components to reduce the occurrence of floating effects.

6. Crosstalk EffectDue to factors such as dense layout of PCB signal lines or electromagnetic interference, different signal lines may experience crosstalk. Crosstalk can lead to degradation of signal quality or abnormal circuit function.

Measures to Reduce Crosstalk Effect:

Optimize PCB layout and design, plan the routing and spacing of signal lines reasonably, and minimize mutual interference between signal lines.

Use shielding covers, shielding materials, or ground isolation techniques to reduce the impact of electromagnetic interference on signals.

Use differential signal transmission lines or increase signal layers to improve anti-interference capability and reduce the occurrence of crosstalk.

Select suitable PCB materials and components to reduce the impact of crosstalk effects.

7. Reflection EffectRefers to the phenomenon in high-speed signal transmission where signals encounter impedance mismatch or incomplete absorption of signal energy by the terminal of the signal transmission line, resulting in signals reflecting back to the original source end. This reflection effect may cause signal waveform distortion, affecting the transmission quality and stability of the circuit.

Measures to Reduce Reflection Effect:

Design signal transmission lines reasonably to ensure impedance matching and minimize impedance mismatch situations.

Use terminal resistors or terminal capacitors to absorb signal energy and reduce signal reflection.

Optimize PCB layout and design to minimize the length of signal transmission lines and reduce signal transmission delay.

Select suitable PCB materials and components to reduce the impact of reflection effects.

8. Shielding EffectThe metal layer or shielding cover on the PCB may shield signals, affecting the transmission range and quality of signals.

Measures to Reduce Shielding Effect:

Design PCB layout reasonably: Try to avoid overlap or proximity between signal lines and shielding areas to minimize the impact of shielding effect.

Choose appropriate shielding materials: Select suitable metal layers or shielding cover materials in PCB design to have good shielding performance while minimizing the impact on signal transmission.

Design suitable grounding structure: A good grounding structure can help reduce the shielding effect of signals and improve signal transmission quality.

Pay attention to signal adjustment: For signals that need to pass through shielding areas, signal adjustment techniques can be employed to minimize the impact of shielding effect, such as increasing signal power or adjusting signal transmission methods.

9. Thermal Expansion EffectTemperature changes may cause thermal expansion or contraction of PCB materials, affecting the dimensional stability of circuit boards and the connection status of components.

Measures to Reduce Thermal Expansion Effect:

Choose appropriate PCB materials: Selecting PCB materials with smaller coefficients of thermal expansion can reduce the impact of thermal expansion on circuits.

Design PCB layout reasonably: During PCB design, try to avoid direct connection between materials with high coefficients of thermal expansion and those with low coefficients to reduce the impact of thermal expansion.

Control soldering temperature: Control soldering temperature and time during the soldering process to avoid excessive temperature leading to solder joint failure or component displacement.

Use support structures: Adding appropriate support structures in PCB design can reduce PCB bending deformation, improving the stability and reliability of the PCB.

10. Ground Hole EffectThere are many ground holes on the PCB. When ground holes are close to signal lines or other ground holes, ground hole effect may occur, affecting the stability of signal transmission.

Measures to Reduce Ground Hole Effect:

Design ground holes reasonably: Design appropriate parameters for ground holes, such as diameter, pitch, copper foil diameter, etc., to ensure impedance matching and consistency of ground holes, reducing ground hole inductance and crosstalk effects.

Use ground hole filling: Ground hole filling techniques can be employed in PCB design to fill ground holes, reducing their impact on signal transmission and improving PCB performance stability.

Optimize layout: Plan PCB layout reasonably to minimize the number and density of ground holes, reducing their impact on circuits.

Adjust interlayer stacking: Choose PCB layer stacking methods appropriately to minimize ground holes between inner and outer layers, reducing the impact of ground hole effect.

11. Filling EffectThe filling material on the PCB may affect signal transmission. For example, differences in the dielectric constant of the filling material may cause changes in signal transmission speed or signal attenuation.

Measures to Reduce Filling Effect:

Choose filling material reasonably: Select filling materials with a dielectric constant close to that of the PCB material to reduce the impact of dielectric constant differences on signal transmission.

Control the thickness of filling material: Properly control the thickness of filling material to avoid excessive thickness, which could lengthen the signal transmission path and increase attenuation.

Optimize PCB layout: During PCB design, minimize the impact on signal transmission paths, plan filling areas reasonably, and avoid interference from filling materials on signal transmission paths.

Use low-loss filling materials: Choose filling materials with low resistance and dielectric loss to minimize attenuation and distortion during signal transmission.

12. Temperature Drift EffectTemperature changes on the PCB may cause thermal expansion or contraction of circuit board materials, thereby affecting the dimensional stability of the circuit board and the connection status of components.

Measures to Reduce Temperature Drift Effect:

Choose PCB materials reasonably: Select PCB materials with good thermal stability and dimensional stability to reduce the impact of temperature changes on the PCB.

Control soldering temperature: During the soldering process, control soldering temperature and time properly to avoid excessive soldering temperature leading to damage or breakage of components and solder joints.

Optimize PCB layout: Plan PCB layout reasonably to reduce differences in thermal expansion coefficients between components and avoid changes in the connection status of components due to temperature changes.

Temperature environment control: Control temperature changes in the PCB usage environment to avoid significant temperature shocks to the PCB, thereby reducing the impact of temperature changes on PCB circuits.

13. Crystal EffectDevices such as transistors in PCB routing may be influenced by the surrounding environment, causing changes in device parameters and affecting circuit performance.

Measures to Reduce Crystal Effect:

Rational Layout: Properly plan PCB layout to avoid external interference affecting devices such as transistors and minimize electromagnetic field interference with devices.

Temperature Control: Take measures to control the operating temperature of the PCB board during design and manufacturing to reduce the influence of temperature changes on device parameters and improve circuit stability.

Choose Appropriate Devices: Select transistors and other devices with good anti-interference and stability to reduce the impact of crystal effect on the circuit.

Design Compensation Circuits: In PCB design, compensation circuits can be used to correct drift in device parameters, improving circuit performance and stability.

14. Restricted EffectThere are some restricted areas on the PCB, such as edges, power supply areas, etc., which may impose certain limitations or impacts on signal transmission or routing.

Measures to Reduce Restricted Effect:

Rational Planning of Layout: During PCB design, plan the layout reasonably to avoid placing sensitive signal lines or components near restricted areas, reducing the impact of restrictions.

Electromagnetic Shielding: For areas prone to electromagnetic interference in restricted areas, electromagnetic shielding measures can be adopted, such as placing metal shielding covers around sensitive areas to reduce the impact of external electromagnetic interference on the circuit.

Optimization of Power Supply Design: For possible power supply instability or noise issues in power supply areas, measures such as optimizing power supply design, adding filtering circuits, and reducing power supply noise can be taken to improve power supply stability and circuit performance.

Fine Routing: When routing in restricted areas, adopt fine routing methods as much as possible to reduce restrictions or elongation of signal transmission paths, improving signal transmission rate and stability.

15. Landmine EffectHidden problems or faults on PCB boards may suddenly appear during subsequent testing or use, causing unexpected impacts or damage to the circuit board.

Measures to Reduce Landmine Effect:

Strict Quality Control: During PCB production, strictly control the quality of each process to ensure that each component and circuit connection meets specifications, reducing hidden dangers.

Perfect Testing Procedures: Establish comprehensive testing and inspection procedures to conduct comprehensive testing and inspection of PCB circuits, promptly identify and repair potential problems.

Use Reliable Components: Choose components and materials with high reliability and stable quality to reduce the probability of failure and minimize the occurrence of landmine effects.

Strengthen Maintenance: Regularly maintain and upkeep produced PCB circuits, promptly identify and repair potential problems, improving circuit reliability and stability.

Online messageinquiry

What is “component placement” in PCB?

- Week of hot material

- Material in short supply seckilling

| model | brand | Quote |

|---|---|---|

| RB751G-40T2R | ROHM Semiconductor | |

| CDZVT2R20B | ROHM Semiconductor | |

| TL431ACLPR | Texas Instruments | |

| MC33074DR2G | onsemi | |

| BD71847AMWV-E2 | ROHM Semiconductor |

| model | brand | To snap up |

|---|---|---|

| ESR03EZPJ151 | ROHM Semiconductor | |

| BU33JA2MNVX-CTL | ROHM Semiconductor | |

| IPZ40N04S5L4R8ATMA1 | Infineon Technologies | |

| TPS63050YFFR | Texas Instruments | |

| BP3621 | ROHM Semiconductor | |

| STM32F429IGT6 | STMicroelectronics |

- Week of ranking

- Month ranking

Qr code of ameya360 official account

Identify TWO-DIMENSIONAL code, you can pay attention to

Please enter the verification code in the image below: