- Ameya360 Component Supply Platform >

- Trade news >

- 8-Inch Wafer Fabs to Increase Monthly Production Capacity by 14% in 2026

8-Inch Wafer Fabs to Increase Monthly Production Capacity by 14% in 2026

Source to China Times, the International Semiconductor Industry Association (SEMI) forecasts that from 2023 to 2026, the global semiconductor industry will add 12 new 8-inch wafer fabs, with 8-inch fab monthly production capacity increasing by 14% to a historic high of 7.7 million wafers. In response, UMC stated that from a supply and demand perspective, capacity growth still lags behind demand growth. UMC emphasized that it remains optimistic about the future of the 8-inch wafer market, thanks to ongoing advancements in special processes and differentiation.

SEMI notes that the continuous rise in the penetration rate of electric vehicles (EVs) worldwide is driving substantial growth in the demand for inverters and charging stations. The future mass adoption of EVs is the primary driver for increased investments in 8-inch fabs and the continued expansion of global 8-inch fab capacity.

Examining the situation of new 8-inch fabs in various countries, Southeast Asia will see the largest capacity increase, with a growth rate of approximately 32%. SEMI predicts that China’s 8-inch fab capacity will follow, with an increase of about 22%, reaching a monthly production capacity of 1.7 million wafers. The United States, Europe, the Middle East, and Taiwan are expected to have growth rates of approximately 14%, 11%, and 7%, respectively.

SEMI reports that by 2023, China’s 8-inch fab capacity will account for approximately 22% of the global total, with Japan at around 16%, Taiwan at around 15%, and Europe, the Middle East, and the United States each at about 14%. Furthermore, to meet future market demand, suppliers such as Bosch, Infineon, Mitsubishi, Onsemi, and STMicroelectronics are accelerating their 8-inch fab capacity expansion. It is estimated that from 2023 to 2026, the 8-inch fab capacity for automotive and power semiconductors will increase by 34%.

Concerns have been raised about potential oversupply as global 8-inch fabs expand, but UMC, a major semiconductor foundry, states that given the current rate of 8-inch fab expansion worldwide, the increase in capacity is relatively modest compared to demand. From a supply and demand perspective, it is certain that capacity growth will not keep pace with the growing global demand for 8-inch wafers.

UMC further notes that while 8-inch fabs are increasing, demand is unlikely to remain stagnant. Currently, the majority of semiconductor fabs being built worldwide are 12-inch fabs, making the expansion of 8-inch fabs relatively limited, and the supply-demand balance has not worsened.

Online messageinquiry

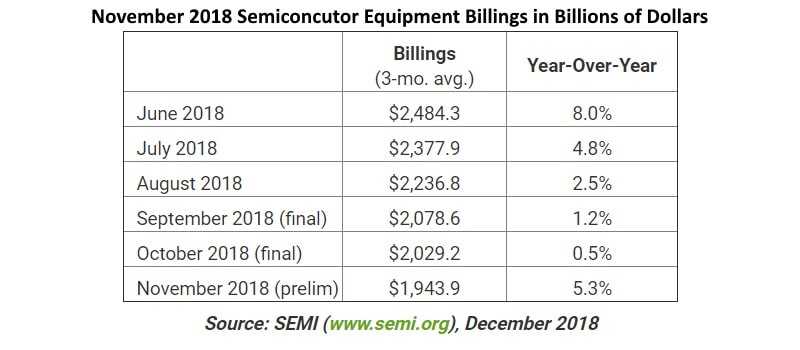

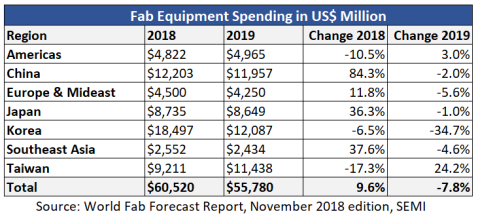

Fab Tool Sales Expected to Decline in 2019

Fab Tool Sales Slip to $15.8 Billion in Q3

- Week of hot material

- Material in short supply seckilling

| model | brand | Quote |

|---|---|---|

| CDZVT2R20B | ROHM Semiconductor | |

| RB751G-40T2R | ROHM Semiconductor | |

| TL431ACLPR | Texas Instruments | |

| BD71847AMWV-E2 | ROHM Semiconductor | |

| MC33074DR2G | onsemi |

| model | brand | To snap up |

|---|---|---|

| IPZ40N04S5L4R8ATMA1 | Infineon Technologies | |

| STM32F429IGT6 | STMicroelectronics | |

| BP3621 | ROHM Semiconductor | |

| BU33JA2MNVX-CTL | ROHM Semiconductor | |

| TPS63050YFFR | Texas Instruments | |

| ESR03EZPJ151 | ROHM Semiconductor |

- Week of ranking

- Month ranking

Qr code of ameya360 official account

Identify TWO-DIMENSIONAL code, you can pay attention to

Please enter the verification code in the image below: