- Ameya360 Component Supply Platform >

- Trade news >

- What is High-Speed PCB? What is Low-Speed PCB?

What is High-Speed PCB? What is Low-Speed PCB?

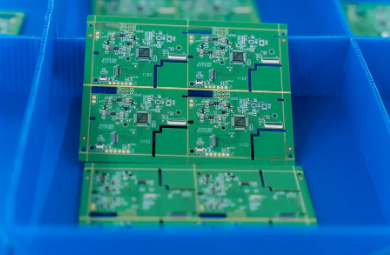

Printed Circuit Boards (PCBs) form the backbone of electronic devices, serving as the fundamental platform for connecting various components. High-speed and low-speed PCBs represent two distinct categories, each tailored to meet specific requirements in the vast landscape of electronic systems. Understanding the differences between high-speed vs low-speed PCBs is crucial for engineers and designers aiming to optimize performance, cost, and reliability in their designs.

What is High-Speed PCB?High-speed PCBs are engineered to facilitate the transmission of data at elevated frequencies without compromising signal integrity. These PCBs are prevalent in applications where rapid data transfer is imperative, such as telecommunications infrastructure, high-performance computing, data centers, and high-frequency RF systems like radar and wireless communication.

High-Speed PCB

Signal Integrity:

High-speed PCBs prioritize signal integrity maintenance. Engineers meticulously design transmission lines to minimize impedance mismatches, signal reflections, and electromagnetic interference (EMI) that could compromise data accuracy and reliability. Advanced simulation and analysis tools are employed to predict and mitigate potential issues.

Routing and Trace Length:

These PCBs necessitate controlled impedance routing and shorter trace lengths to mitigate signal degradation caused by factors like capacitance and inductance. Precise impedance matching across the entire signal path is critical to prevent signal loss and distortion.

Component Placement:

Strategic component placement minimizes signal path length, reduces crosstalk between traces, and optimizes signal flow. Special attention is paid to the arrangement of high-speed signal traces and critical components to minimize signal skew and distortion.

Material Selection:

High-speed PCBs often utilize specialized materials with specific dielectric constants and lower-loss tangents to enhance signal propagation and minimize losses, ensuring the integrity of high-frequency signals.

Grounding and Power Distribution:

Proper grounding techniques and meticulous power distribution strategies are employed to minimize noise and maintain signal integrity throughout the PCB.

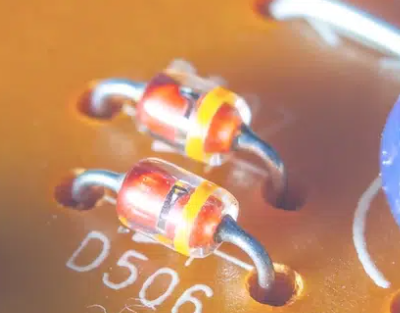

What is Low-Speed PCB?In contrast, Low-Speed PCBs cater to applications where data transmission occurs at slower rates or lower frequencies. These PCBs are commonly found in simpler electronic devices, control systems, automotive electronics, and various consumer electronics.

Low-Speed PCB

Simplicity and Cost-Effectiveness:

Low-Speed PCB designs are characterized by simplicity. They entail less stringent requirements for impedance control and signal integrity compared to their high-speed counterparts, often resulting in more cost-effective manufacturing processes.

Routing and Component Tolerance:

These designs typically feature less complex routing and wider tolerances for component placement and routing. This flexibility simplifies the design process, reducing manufacturing costs and lead times.

Material Considerations:

Material choices for Low-Speed PCBs may differ from those used in High-Speed PCBs. They prioritize cost efficiency without compromising the functionality required for their designated applications.

High-Speed vs Low-Speed PCBs – What Are the Differences?Frequency Handling:

High-Speed PCBs excel in managing high-frequency signal transmission, whereas Low-Speed PCBs operate at lower frequencies.

Design Complexity:

High-Speed PCBs demand meticulous design methodologies and stringent considerations for signal integrity, whereas Low-Speed PCBs offer greater design flexibility due to their lower frequency requirements.

Cost and Manufacturing:

High-Speed PCBs tend to be more expensive to manufacture due to the need for specialized materials and intricate design requirements, while Low-Speed PCBs are comparatively more cost-effective.

ConclusionIn the realm of electronics, High-Speed and Low-Speed PCBs cater to distinct operational needs and frequencies, influencing factors like signal integrity, cost-effectiveness, and manufacturing complexity. As technology continues to evolve, the demand for faster data transmission and heightened performance amplifies the significance of High-Speed PCBs in shaping modern electronic systems.

Understanding the differences between high-speed vs low-speed PCBs empowers engineers and designers to make informed decisions, selecting the most suitable PCB type that aligns precisely with the operational requirements of their applications. The symbiotic relationship between High-speed and low-speed PCBs contributes significantly to the functionality and efficiency of the devices we rely on daily, embodying the intricate synergy between design, functionality, and technology.

Online messageinquiry

What is “component placement” in PCB?

15 Common PCB Circuit Effects

- Week of hot material

- Material in short supply seckilling

| model | brand | Quote |

|---|---|---|

| MC33074DR2G | onsemi | |

| CDZVT2R20B | ROHM Semiconductor | |

| TL431ACLPR | Texas Instruments | |

| BD71847AMWV-E2 | ROHM Semiconductor | |

| RB751G-40T2R | ROHM Semiconductor |

| model | brand | To snap up |

|---|---|---|

| ESR03EZPJ151 | ROHM Semiconductor | |

| BP3621 | ROHM Semiconductor | |

| IPZ40N04S5L4R8ATMA1 | Infineon Technologies | |

| TPS63050YFFR | Texas Instruments | |

| BU33JA2MNVX-CTL | ROHM Semiconductor | |

| STM32F429IGT6 | STMicroelectronics |

- Week of ranking

- Month ranking

Qr code of ameya360 official account

Identify TWO-DIMENSIONAL code, you can pay attention to

Please enter the verification code in the image below: