Ceramic capacitors vs. electrolytic capacitors – what are the differences?

In the vast realm of electronic components, capacitors stand as fundamental devices for storing and releasing electrical energy. Among the diverse spectrum of capacitors available, two prominent types—ceramic capacitors vs. electrolytic capacitors —emerge with distinct characteristics, applications, and performance attributes. Delving deeper into their nuances is crucial for discerning engineers, hobbyists, and electronic enthusiasts aiming to optimize circuit designs and performance.

What is capacitor?Capacitors, as passive electronic components, are pivotal in numerous circuit applications. They consist of two conductive plates (electrodes) separated by a dielectric material. When a voltage is applied across these plates, they accumulate and store electrical charge, which can be discharged when required, aiding in various electrical functions within circuits.

Ceramic Capacitors

Characteristics:

Ceramic capacitors are renowned for their reliability, stability, and an extensive range of capacitance values. These capacitors utilize ceramic materials with a metal layer serving as the electrodes. They are available in diverse shapes and sizes, encompassing both surface-mount (SMD) and through-hole configurations.

Advantages:

Low ESR (Equivalent Series Resistance): Ceramic capacitors are known for their low ESR, enabling swift responses to voltage fluctuations and changes.

High Frequency Response: Their minimal parasitic effects make ceramic capacitors highly suitable for high-frequency applications.

Stability and Temperature Performance: They exhibit commendable stability across temperature variations, ensuring consistent performance.

Limitations:

Capacitance Variability: Ceramic capacitors may demonstrate significant variations in capacitance concerning voltage and temperature fluctuations.

Piezoelectric Effect: Certain types of ceramic capacitors exhibit the piezoelectric effect, generating electrical charge under mechanical stress.

Applications:

Ceramic capacitors find extensive usage in high-frequency circuits, decoupling applications, signal filtering, and as crucial components in power supply bypass circuits.

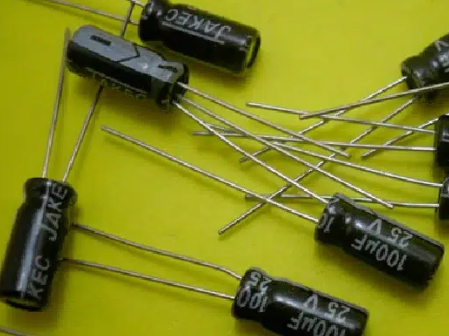

Electrolytic Capacitors

Characteristics:

Electrolytic capacitors employ an electrolyte as the dielectric material between their plates. They primarily exist in two major types: aluminum electrolytic and tantalum electrolytic capacitors.

Advantages:

High Capacitance: Electrolytic capacitors offer substantially higher capacitance values compared to ceramic capacitors, making them suitable for applications requiring significant energy storage.

Cost-Effectiveness: They are generally more cost-effective for higher capacitance requirements.

Polarity: Electrolytic capacitors are polarized, rendering them ideal for DC circuit applications.

Limitations:

Higher ESR: Electrolytic capacitors typically exhibit higher ESR compared to ceramic counterparts.

Temperature and Lifespan Sensitivity: They are more susceptible to temperature variations and have a limited operational lifespan compared to ceramics.

Applications:

Owing to their higher capacitance values, electrolytic capacitors find applications in power supply filtering, audio systems, and situations demanding substantial energy storage capabilities.

Ceramic capacitors vs. electrolytic capacitors – what are the differences?Capacitance Range:

Ceramic capacitors offer a lower capacitance range in comparison to electrolytic capacitors. For high-frequency applications or instances necessitating low ESR, ceramic capacitors are preferred. However, for applications requiring higher capacitance values, electrolytic capacitors become the go-to choice.

Frequency Response:

Ceramic capacitors exhibit remarkable performance in high-frequency applications due to their minimal parasitic effects and low ESR. Hence, they are particularly well-suited for RF circuits and high-speed digital designs. On the other hand, electrolytic capacitors, with higher ESR, are more adept in low-frequency applications.

Size and Form Factor:

Ceramic capacitors possess a smaller form factor and are available in compact surface-mount packages, making them ideal for space-constrained designs. In contrast, electrolytic capacitors are relatively larger and are commonly utilized in applications where space availability isn’t a limiting factor.

Cost Considerations:

Ceramic capacitors offer cost-effectiveness for lower capacitance values, while electrolytic capacitors provide cost advantages for applications requiring higher capacitance values, making cost a crucial factor in the selection process.

ConclusionIn conclusion, while both ceramic and electrolytic capacitors exhibit distinct attributes and serve varied purposes, their selection profoundly impacts the performance and reliability of electronic circuits across diverse applications. The optimal choice hinges on an intricate understanding of specific application requirements, encompassing capacitance range, frequency response, size constraints, cost considerations, and voltage stability.

在线留言询价

- 一周热料

- 紧缺物料秒杀

| 型号 | 品牌 | 询价 |

|---|---|---|

| BD71847AMWV-E2 | ROHM Semiconductor | |

| MC33074DR2G | onsemi | |

| TL431ACLPR | Texas Instruments | |

| CDZVT2R20B | ROHM Semiconductor | |

| RB751G-40T2R | ROHM Semiconductor |

| 型号 | 品牌 | 抢购 |

|---|---|---|

| ESR03EZPJ151 | ROHM Semiconductor | |

| BP3621 | ROHM Semiconductor | |

| TPS63050YFFR | Texas Instruments | |

| BU33JA2MNVX-CTL | ROHM Semiconductor | |

| IPZ40N04S5L4R8ATMA1 | Infineon Technologies | |

| STM32F429IGT6 | STMicroelectronics |

- 周排行榜

- 月排行榜

AMEYA360公众号二维码

识别二维码,即可关注

请输入下方图片中的验证码: