- Ameya360 Component Supply Platform >

- Trade news >

- Nidec to Expand Its Production Capacity for Water-cooling Modules

Nidec to Expand Its Production Capacity for Water-cooling Modules

Nidec Corporation (TSE: 6594; OTC US: NJDCY) (“Nidec” or the “Company”) today announced that it will enhance its CDU (Coolant Distribution Unit) production line in Thailand, the Company’s manufacturing base for water-cooling modules for servers, to increase the factory’s monthly CDU production capacity from 200 to 2,000 units by June 2024.

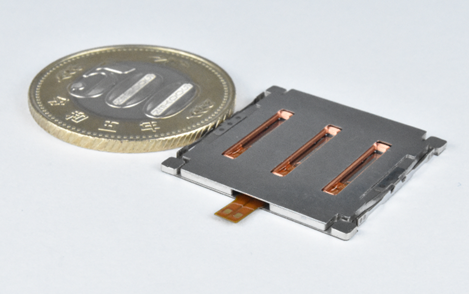

Nidec’s water-cooling module

The CDU production capacity expansion is in response to the adoption by Supermicro, an American AI server manufacturer. The jointly developed with Supermicro 100 to 250 kW products will be manufactured at the Ayutthaya Plant in Thailand, where the existing line has been expanded.

So far, the fan-based air-cooling method has mainly been employed for computing servers in data centers, research institutes, and other similar facilities. However, in AI, the market expected to grow going forward, semiconductor-based arithmetic units (CPUs and GPUs) that utilize AI to process learning information with big data generate significantly more heat than their predecessors. Thus, as the air-cooling method, which relies on air-conditioning equipment, is insufficient to cool a myriad of servers lined up in a building. This is why the water-cooling system, whose cooling capability is far superior to the air-cooling system’s, is expected to become indispensable in the future.

As the water-cooling module market is forecast to continue its growth, Nidec intends to expand its monthly CDU production capacity to more than 3,000 units in the future, while expecting the size of related products’ markets to be 10 billion yen in FY2023, and more than 80 billion yen in FY2024.

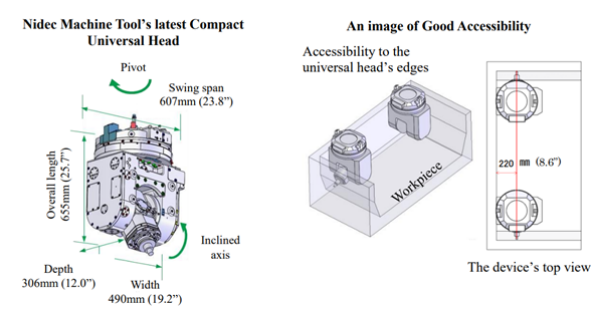

Nidec’s cooling systems employ a liquid-to-liquid method, where cooling modules installed in each server supply cooling water via metal pipes to directly cool each server’s computing devices. The systems comprise a CDU (coolant distribution unit), a cooling water distributor; a CDM (coolant distribution manifold), a cooling water piping; and an LCM (liquid cooling module), a water-cooling module.

The aforementioned product features the redundancy of its pumps, electricity sources, circuit substrates, and other important units, which are all in pairs to improve the system’s reliability. Additionally, those units are replaceable even during maintenance, without stopping its cooling system, to keep the server operating (a hot-swap functionality).

To contribute to the development of the world’s AI, Nidec stays committed to working as a comprehensive thermal solution manufacturer to provide products that perfectly reflect people’s needs. By offering proposals a step ahead of the competition, and with an enhanced lineup of its high-reliability products, Nidec presses ahead to become a market leader.

Online messageinquiry

- Week of hot material

- Material in short supply seckilling

| model | brand | Quote |

|---|---|---|

| BD71847AMWV-E2 | ROHM Semiconductor | |

| TL431ACLPR | Texas Instruments | |

| CDZVT2R20B | ROHM Semiconductor | |

| MC33074DR2G | onsemi | |

| RB751G-40T2R | ROHM Semiconductor |

| model | brand | To snap up |

|---|---|---|

| IPZ40N04S5L4R8ATMA1 | Infineon Technologies | |

| ESR03EZPJ151 | ROHM Semiconductor | |

| BP3621 | ROHM Semiconductor | |

| BU33JA2MNVX-CTL | ROHM Semiconductor | |

| TPS63050YFFR | Texas Instruments | |

| STM32F429IGT6 | STMicroelectronics |

- Week of ranking

- Month ranking

Qr code of ameya360 official account

Identify TWO-DIMENSIONAL code, you can pay attention to

Please enter the verification code in the image below: