- Ameya360 Component Supply Platform >

- Trade news >

- STMicroelectronics Automotive-grade Devices Feature Enhanced Power Densities

STMicroelectronics Automotive-grade Devices Feature Enhanced Power Densities

STMicroelectronics has introduced five power-semiconductor bridges in popular configurations, housed in its advanced ACEPACK SMIT package that eases assembly and enhances power density over conventional TO-style packages.

Engineers can choose from two STPOWER 650V MOSFET half bridges, a 600V ultrafast diode bridge, a 1.2kV half-controlled full-wave rectifier, and a 1.2kV thyristor-controlled bridge leg. All devices meet automotive-industry requirements and are suitable for electric vehicle on-board chargers (OBC) and DC/DC converters, as well as industrial power conversion.

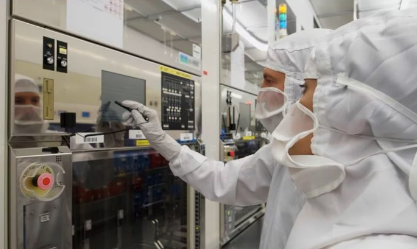

ST’s ACEPACK SMIT surface mounted package delivers the easy handling of an insulated package with the thermal efficiency of an exposed drain. It allows direct-bonded copper (DBC) die attachment for efficient top-side cooling. The 4.6cm2 exposed metal topside of the ACEPACK SMIT permits easy attachment of a planar heatsink. This creates a space-saving low profile that maximizes thermal dissipation for greater reliability at high power. The module and heatsink can be placed using automated inline equipment, which saves manual processes and boosts productivity.

While minimizing the stack height and enhancing power density, the topside cooling design and 32.7-by-22.5mm package footprint allow 6.6mm lead-to-lead creepage distance. The tab-to-lead insulation is 4.5kVrms. The package also has low parasitic inductance and capacitance.

The SH68N65DM6AG and SH32N65DM6AG 650V-MDmesh DM6 MOSFET half bridges now available in ACEPACK SMIT are AQG-324 qualified. Their Rds(on) (max) of 41m? in the SH68N65DM6AG and 97m? in the SH32N65DM6AG ensures high electrical efficiency and low thermal dissipation. They can be used in DC/DC converters for both OBC and high voltage to low voltage section. Their multi-role flexibility helps streamline inventory and simplify procurement.

The STTH60RQ06-M2Y 600V, 60A full-wave bridge rectifier comprises ultrafast diodes with soft recovery characteristic and is PPAP capable for use in automotive applications.

The STTD6050H-12M2Y 1.2kV, 60A half-controlled single-phase AC/DC bridge rectifier is AEC-Q101 qualified and has high noise immunity with dV/dt of 1kV/μs.

The STTN6050H-12M1Y is a 1.2kV, 60A half bridge that comprises two internally connected thyristors (silicon-controlled rectifiers – SCRs). AEC-Q101 qualified, it can be used in automotive OBCs and charging stations and industrial applications such as AC/DC conversion in motor drives and power supplies, single- and tri-phase controlled rectifier bridges, totem-pole power-factor correction, and solid-state relay.

Online messageinquiry

Embedded AI Solutions Ease ML Development

STMicroelectronics and eYs3D Microelectronics to Highlight 3D Stereo-vision Camera at CES 2023

- Week of hot material

- Material in short supply seckilling

| model | brand | Quote |

|---|---|---|

| BD71847AMWV-E2 | ROHM Semiconductor | |

| RB751G-40T2R | ROHM Semiconductor | |

| CDZVT2R20B | ROHM Semiconductor | |

| TL431ACLPR | Texas Instruments | |

| MC33074DR2G | onsemi |

| model | brand | To snap up |

|---|---|---|

| STM32F429IGT6 | STMicroelectronics | |

| ESR03EZPJ151 | ROHM Semiconductor | |

| BP3621 | ROHM Semiconductor | |

| IPZ40N04S5L4R8ATMA1 | Infineon Technologies | |

| TPS63050YFFR | Texas Instruments | |

| BU33JA2MNVX-CTL | ROHM Semiconductor |

- Week of ranking

- Month ranking

Qr code of ameya360 official account

Identify TWO-DIMENSIONAL code, you can pay attention to

Please enter the verification code in the image below: