- Ameya360 Component Supply Platform >

- Trade news >

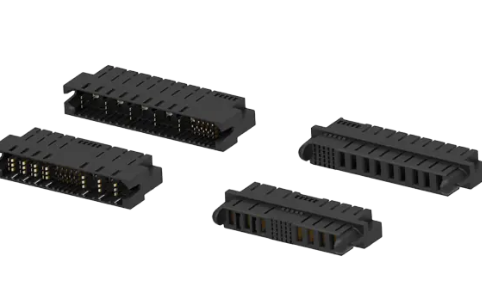

- TE Connectivity Blind Mating Mobile Charging Connectors

TE Connectivity Blind Mating Mobile Charging Connectors

TE Connectivity's (TE) Blind Mating Mobile Charging Connectors are intended for smaller mobile robots and autonomous vehicles typically used in warehouse environments. Autonomous mobile robots (AMR) are used mostly for material handling (picking, movement, storage, and sorting) in the warehouse automation space.

TE's Blind Mating Mobile Charging Connectors are available in 2- and 3-power contact options with up to eight signal contacts to ease installation and rework cycle times. The series offers a high mating cycle life and serves as a modular solution that will support different configurations, data, and sensing.

FEATURES

Robust design for high-cycle life

Designed for a minimum of 12,000 mating cycles

Low insertion force power contacts

Spring probe signal contacts

Connection flexibility

2 and 3 power contact options

Up to 50A and up to 125V

Up to 40A per line at up to 100V

Terminates to 10AWG or 8AWG stranded copper wire

First make, last break contact for use in grounding, system enabling, or applications that require charging two battery strings independently

Touch safe contacts for extra safety if rework is needed

Blind mate capability

Allows for the misalignment of at least ±15mm for x and ±10 for the y direction

± Approx. 5° for z direction (mating)

Up to 8x signal contacts

Up to 0.5A per line

Terminates to 30AWG to 22AWG stranded wire

Rear pluggable interface to ease installation and rework cycle times

Spring probe contacts for high cycle life

Utilizes Mini Universal MATE-N-LOKII Connector interface for signal contact mating

APPLICATIONS

Charging for autonomous mobile robots/automated guided vehicles (AMR/AGV)

Blind mate battery charging

Industrial

Hospitality

Retail

Medical

Online messageinquiry

- Week of hot material

- Material in short supply seckilling

| model | brand | Quote |

|---|---|---|

| CDZVT2R20B | ROHM Semiconductor | |

| BD71847AMWV-E2 | ROHM Semiconductor | |

| RB751G-40T2R | ROHM Semiconductor | |

| MC33074DR2G | onsemi | |

| TL431ACLPR | Texas Instruments |

| model | brand | To snap up |

|---|---|---|

| ESR03EZPJ151 | ROHM Semiconductor | |

| STM32F429IGT6 | STMicroelectronics | |

| IPZ40N04S5L4R8ATMA1 | Infineon Technologies | |

| BP3621 | ROHM Semiconductor | |

| TPS63050YFFR | Texas Instruments | |

| BU33JA2MNVX-CTL | ROHM Semiconductor |

- Week of ranking

- Month ranking

Qr code of ameya360 official account

Identify TWO-DIMENSIONAL code, you can pay attention to

Please enter the verification code in the image below: