What are diodes in the circuit board?

PCB diode is one of the most established and most significant electronic gadgets, in spite of the fact that it isn’t quite as well known as its cousin, the semiconductor. Utilized in a wide range of electrical and electronic frameworks, the diode capabilities as a one-way valve for electric flow — it just permits flow to stream in one bearing. This is valuable in changing AC over completely to DC, handling high recurrence signals, controlling voltages, and in different applications.

There are two fundamental sorts of PCB diode. One is an electron tube like the triode. The other kind purposes semiconductors, similar to the semiconductor. Both were concocted from the get-go in the twentieth hundred years.

In this article, you can know everything about PCB diode and related information about this topic.

What are diodes in the circuit board?

A PCB diode is a semiconductor gadget that basically goes about as a one-way switch for current. It permits current to stream effectively in one course, however seriously limits current from streaming the other way.

PCB diode is otherwise called rectifier since it changes substituting current (ac) into throbbing direct current (dc). PCB diode is appraised by their sort, voltage, and current limit.

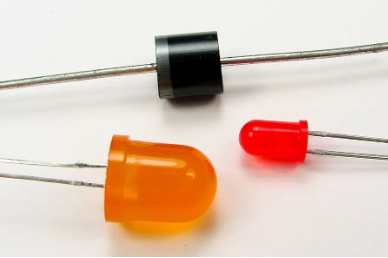

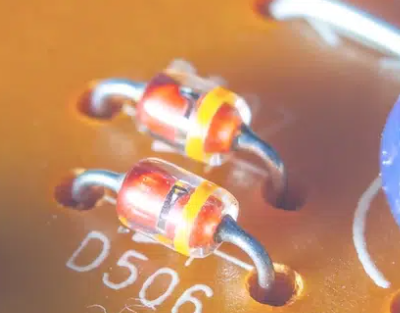

PCB diode is not set in stone by an anode (positive lead) and cathode (adverse lead). PCB diode permits current to stream just when positive voltage is applied to the anode. An assortment of diode setups are shown in this realistic.

PCB diode is accessible in different setups. From left: metal case, stud mount, plastic case with band, plastic case with chamfer, glass case. A PCB diode is the ‘one way’ sign for electrical circuits. The current is permitted to just travel through the PCB diode in one course. Every diode has a positive end, the anode, and an adverse end, the cathode. Current streams from the anode to the cathode, however not the reverse way around.

Why we should use PCB diodes?

A PCB diode is a gadget that permits current to stream in one heading however not the other. This is accomplished through an underlying electric field. Albeit the earliest diodes comprised of scorching wires going through the center of a metal chamber which itself was situated within a glass vacuum tube, present day diodes are semiconductor diodes. As the name recommends, these are produced using semiconductor materials, principally doped silicon.

The most normal application is by a wide margin the utilization of PCB diode for the correction of AC capacity to DC power. Utilizing diodes, various kinds of rectifier circuits can be made, the most fundamental of which are half wave, full wave community tapped, and full scaffold rectifiers. These are critical in hardware power supplies – for instance, a PC’s charger – where an air conditioner current, which comes from the mains power supply, should be changed over completely to a DC current which can then be put away.

Delicate electronic gadgets should be safeguarded from floods in voltage, and the diode is ideal for this. When utilized as voltage insurance gadgets, PCB diode is nonconducting, notwithstanding, they promptly short any high-voltage spike by sending it to the ground where it can’t hurt delicate coordinated circuits. For this utilization, particular diodes known as “transient voltage silencers” are planned. These can deal with huge power spikes throughout brief time frame periods which would ordinarily harm touchy parts.

Characteristics of diode

Fundamental static attributes of PCB diode are the forward voltage VF and forward current IF, and the opposite voltage and current VR and IR.

The region encompassed by the orange ran line in the chart on the right shows the usable area of amending diodes. In particular, this is the region inside the scope of admissible IF, and inside the breakdown voltage range in the opposite bearing. It ought to be noticed that the region encased by the green ran line is the usable area of Zener diodes, albeit these are not examined in this part. This region isn’t usable for different diodes, and assuming this region is placed unbounded on the IR, gadget disappointment might happen.

Reverse Recovery Time is when, from the state wherein a voltage is applied in the forward heading and forward current In the event that is streaming, the voltage is shifted to the opposite course and the converse current IR gets back to the consistent state (basically zero).

As shown in the graph on the right, when the gadget changes from the ON-state in which an In the event that is streaming to the OFF-state, in a perfect world IF would quickly go to nothing. Yet, in reality, zero is passed, and a converse current IR streams quickly, which recuperates to focus in time Reverse Recovery Time. The more limited Reverse Recovery Time is, the better is the gadget trademark.

The capacitance Ct is the capacitance of the actual diode, and has a similar impact as a capacitor. As in the chart on the right, when a PCB diode is turned here and there, assuming Ct is huge, the supposed adjusting of the waveform turns out to be more articulated, and sometimes there might be the issue that the gadget starts switch off activity before an applied voltage arrives at a full level because of time constants. In a rapid exchanging circuit, diodes with a low Ct are attractive.

在线留言询价

What is “component placement” in PCB?

15 Common PCB Circuit Effects

- 一周热料

- 紧缺物料秒杀

| 型号 | 品牌 | 询价 |

|---|---|---|

| BD71847AMWV-E2 | ROHM Semiconductor | |

| MC33074DR2G | onsemi | |

| RB751G-40T2R | ROHM Semiconductor | |

| CDZVT2R20B | ROHM Semiconductor | |

| TL431ACLPR | Texas Instruments |

| 型号 | 品牌 | 抢购 |

|---|---|---|

| ESR03EZPJ151 | ROHM Semiconductor | |

| BP3621 | ROHM Semiconductor | |

| TPS63050YFFR | Texas Instruments | |

| STM32F429IGT6 | STMicroelectronics | |

| BU33JA2MNVX-CTL | ROHM Semiconductor | |

| IPZ40N04S5L4R8ATMA1 | Infineon Technologies |

- 周排行榜

- 月排行榜

AMEYA360公众号二维码

识别二维码,即可关注

请输入下方图片中的验证码: