- Ameya360 Component Supply Platform >

- Trade news >

- ROHM Completes Demonstration of Manufacturing Process Optimization – by applying Quanmatic's Quantum Technology

ROHM Completes Demonstration of Manufacturing Process Optimization – by applying Quanmatic's Quantum Technology

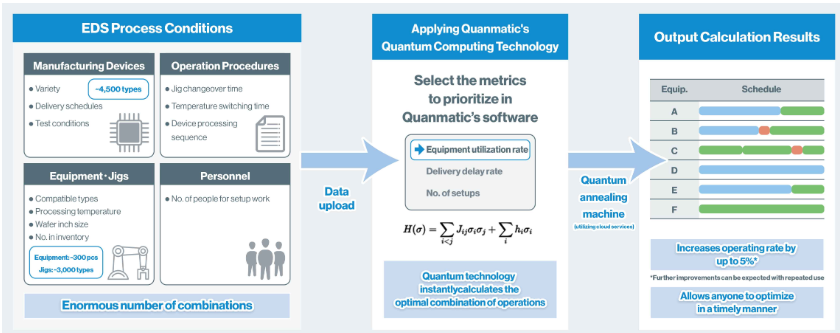

From January 2023, ROHM has been collaborating with Quanmatic to introduce quantum technology into the EDS (Electrical Die Sorting) process, conducting demonstrations aimed at optimizing combinations during manufacturing. Today, ROHM and Quanmatic announce that, as certain benchmarks have been met regarding production efficiency, both companies plan on carrying out full-scale implementation in April 2024. This represents the world's first demonstration of manufacturing process optimization using quantum technology in a large-scale mass production line at a semiconductor manufacturing plant.

In recent years, the use of quantum technology has been explored in various fields, in particular quantum annealing methods*2 being introduced in the area of combinatorial optimization, such as for delivery route optimization in the logistics industry. At the same time, in the semiconductor industry, as the manufacturing process becomes more extensive the possible combinations increase exponentially. On top, the large number of constraints makes it hard to obtain an optimal solution. Therefore, the application of quantum technology was limited to processes on a scale that could be approximated by classical computers.

For example, in the EDS process, the number of combinations involving manufacturing devices, test equipment/conditions, and other factors is so large despite being only a part of the entire system. This made it extremely difficult to derive a solution that optimizes the manufacturing process. As a result, in the past it was common to perform operations (process allocation) based on basic calculation rules, utilizing accumulated knowledge and expertise.

In this context, in January 2023 ROHM and Quanmatic began exploring an operating system using quantum solutions that take into account various constraints in the EDS process. In September 2023 both companies succeeded in building a prototype by combining Quanmatic’s product that improves quantum computing efficiency based on research conducted at Waseda University and Keio University together with a computational framework. The specialized formulation technology involved leverages quantum and classical computation techniques as well as the vast knowledge, expertise, and data accumulated by ROHM to date.

After testing and validating the prototype at ROHM’s domestic and overseas factories, the results showed that key performance indicators such as utilization and delivery delay rates could be improved by several percentage points. In addition, implementing algorithm significantly reduces computation time, enabling timely and optimal operation in response to changes in manufacturing conditions.

Going forward, both companies will work to further deepen their collaboration to improve the accuracy of the manufacturing system through a series of trial operations at overseas plants, with the goal of full-scale introduction in April 2024.

Nozomu Togawa, CSO and Co-Founder of Quanmatic / Professor, Faculty of Science and Engineering, Waseda University“This result is an example of a highly mathematical optimization calculation method researched at a university being applied in the real world. The aim: Providing semiconductor products through a supply chain that is continually optimized on a daily basis using quantum-related methods – which holds great significance as a large-scale practical application of quantum technology. We believe that the accumulation of such achievements will lay the foundation for realizing the Japanese government’s ‘Future Vision of a Quantum Society’ (a society in which 10 million people will be using quantum technology by 2030).”

Tetsuo Tateishi, Member of the Board, Senior Corporate Officer and CTO, ROHM Co., Ltd.“As the role of semiconductors becomes increasingly important to achieving a decarbonized society, ensuring stable supply has become a societal issue. The development of an operational system suitable for large-scale mass production lines using quantum technology represents a major step forward for the semiconductor manufacturing industry, enabling real-time optimization of production processes. Going beyond the current situation, we will accelerate the introduction of quantum technology and related methods into a wide range of processes, with the goal of strengthening our stable supply system by establishing a more holistically optimized supply chain.”

*1) Electrical Die Sorting - A process for testing the electrical characteristics of chips formed on wafers, essential for ensuring the reliability and improving the yield of semiconductor devices.

*2) Technology proposed by Professor Hidetoshi Nishimori of the Tokyo Institute of Technology that sparked the quantum computing boom when it was offered commercially for the first time in the world by Canada’s D-Wave Systems in 2011. It is considered to be close to social implementation due to its strength in solving combinatorial optimization problems that narrow down application focus.

■About QuanmaticA startup founded in October 2022 by CEO Sumitaka Koga, CTO Shu Tanaka (an Associate Professor of Keio University), and CPO Yosuke Mukasa based on the research of Professor Nozomu Togawa (CSO) of Waseda University, Quanmatic provides computer science algorithms for utilizing quantum-related technologies. With the vision of ‘creating a world where quantum technology is accessible to all,’ Quanmatic continues to develop optimization engines that apply algorithmic intellectual property to business problems while deploying efficient solutions for general-purpose quantum computing technology independent of hardware dependencies.

Online messageinquiry

Industry’s Highest* Rated Power! ROHM Unveils the UCR10C Series of Sintered Metal Shunt Resistors

- Week of hot material

- Material in short supply seckilling

| model | brand | Quote |

|---|---|---|

| RB751G-40T2R | ROHM Semiconductor | |

| CDZVT2R20B | ROHM Semiconductor | |

| BD71847AMWV-E2 | ROHM Semiconductor | |

| TL431ACLPR | Texas Instruments | |

| MC33074DR2G | onsemi |

| model | brand | To snap up |

|---|---|---|

| BP3621 | ROHM Semiconductor | |

| TPS63050YFFR | Texas Instruments | |

| ESR03EZPJ151 | ROHM Semiconductor | |

| STM32F429IGT6 | STMicroelectronics | |

| IPZ40N04S5L4R8ATMA1 | Infineon Technologies | |

| BU33JA2MNVX-CTL | ROHM Semiconductor |

- Week of ranking

- Month ranking

Qr code of ameya360 official account

Identify TWO-DIMENSIONAL code, you can pay attention to

Please enter the verification code in the image below: