Murata Power Solutions MPS Isolated DC-DC Converters

Murata Power Solutions MPS Isolated DC-DC Converters transform 36VDC to 75VDC input into an isolated, regulated 12VDC/17A output. These highly efficient 200W devices are fully protected from overcurrent, overtemperature, and overvoltage faults and come with UL, IEC, and other safety approvals. Additional features include optimized thermal performance, high efficiency of up to 95%, remote on/off enable, and output trim adjustment. Murata Power Solutions MPS Isolated DC-DC Converters are RoHS compliant and packaged within an industry-standard sixteenth-brick format with or without a baseplate. Typical applications include power-over-Ethernet (PoE), telecom, industrial, and servers, storage, and networks (SSN).

FEATURES

36V to 75V input voltage range

Regulated 12VDC/17A output

Industry-standard sixteenth-brick with baseplate (optional)

Optimized thermal performance

High efficiency up to 95%

Overcurrent, overtemperature, and overvoltage protection

Remote on/off enable (negative logic)

Output trim adjustment (-20%, 10%)

2250VDC isolation (input-to-output)

RoHS compliant

Safety approvals

UL 62368-1 3rd edition

IEC 62368-1:2018

CSA-C22.2 No. 62368-1-19

CE and UKCA approved

APPLICATIONS

PoE

SSN

Telecom

Industrial

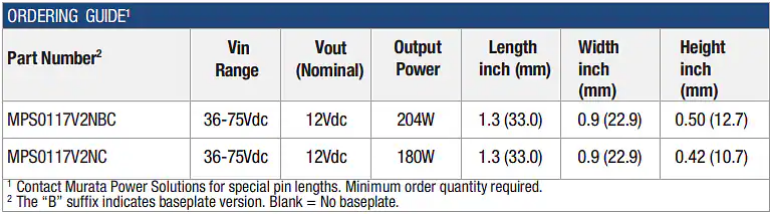

ORDERING GUIDE

在线留言询价

- 一周热料

- 紧缺物料秒杀

| 型号 | 品牌 | 询价 |

|---|---|---|

| BD71847AMWV-E2 | ROHM Semiconductor | |

| MC33074DR2G | onsemi | |

| CDZVT2R20B | ROHM Semiconductor | |

| TL431ACLPR | Texas Instruments | |

| RB751G-40T2R | ROHM Semiconductor |

| 型号 | 品牌 | 抢购 |

|---|---|---|

| TPS63050YFFR | Texas Instruments | |

| BP3621 | ROHM Semiconductor | |

| IPZ40N04S5L4R8ATMA1 | Infineon Technologies | |

| BU33JA2MNVX-CTL | ROHM Semiconductor | |

| STM32F429IGT6 | STMicroelectronics | |

| ESR03EZPJ151 | ROHM Semiconductor |

- 周排行榜

- 月排行榜

AMEYA360公众号二维码

识别二维码,即可关注

请输入下方图片中的验证码: