- Ameya360 Component Supply Platform >

- Trade news >

- What is a paper capacitor?

What is a paper capacitor?

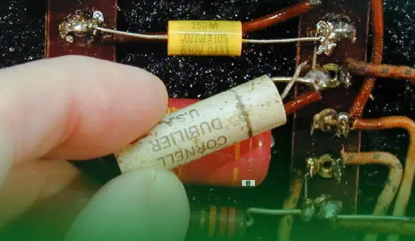

Paper capacitor is one of the basic types of capacitors. Typically, in a capacitor, the conducting materials are separated by a dielectric, and based on the variant used as the dielectric, different types of capacitors are formed. The structure of paper capacitor is similar to other capacitors, such as plastic capacitors. The only difference between the other capacitors and paper capacitors is that the dielectric chosen is paper. Paper capacitors are also called fixed capacitors, in which paper is used as a dielectric, which stores energy in the form of an electric field.

Paper capacitor is used in capacitance values of 1nF to 1uF at power line frequencies and it stores a fixed amount of charge. To care for or protect the dielectric from the environment, dip it in wax or oil.

Paper capacitance value

The capacitance of paper capacitor is measured in farads. The capacitance of paper capacitor ranges from 0.001 to 2.000 microfarads to the high voltage range of 2000V. In the beginning of this capacitor, paper was used as the dielectric between two aluminum sheets but now other materials like plastic are used instead of paper. Paper capacitor is readily available in the 300 picofarad to 4 microfarad range and operates at 600 volts.

How paper capacitors work?

Paper capacitors consist of two metal plates with paper used as the dielectric material between them. There are positive and negative plates in it and when a charge is applied to the plate, the positive plate is attracted to one side and the negative charge is attracted to the other plate. This electrical energy is stored in the form of an electric field, and this collected electrical energy is used by discharging the capacitor. These range from 500pF to 50nF. This results in high leakage current.

Structure of paper capacitor

There are two types of paper capacitors: paper capacitors and metallized paper capacitors.

Paper Capacitor

The construction of this capacitor requires two sheets of aluminum and a piece of paper, which is completely covered with wax to protect it from the elements. A paper capacitor is a fixed capacitor that stores a fixed amount of charge at a fixed value of charge capacitance, with aluminum plates placed between sheets of paper that act as dielectrics, while aluminum acts as electrodes.

Paper is a very poor conductor of electricity, not allowing electric current to pass between the aluminum sheets, but allowing electric fields to pass through it, acting as a barrier to the flow of electricity. The paper and aluminum sheets are rotated into a cylinder shape, and the entire cylinder is coated with wax or plastic resin to protect it from the humidity of the outside air, and two wires are led from the ends of the two aluminum sheets.

Metallized paper capacitor

In metalized paper capacitor, the paper is coated with a thin layer of zinc or aluminum and rotated in the form of a cylinder. The entire cylinder is completely coated with wax to protect it from dust and moisture in the external environment, with metal paper electrodes and paper acting as dielectrics.

Such zinc-coated capacitors are easily destroyed due to chemical effects, which is why aluminum is widely used in the manufacture of such capacitors. Compared with paper capacitors and metal paper capacitors, metal paper capacitors are smaller in size. This is because it has a very thin layer of aluminum compared to the aluminum wrapped in a paper capacitor.

Advantages and disadvantages of paper capacitor

The main advantage of using paper capacitor is that it provides a fixed capacitance value, and the capacitance value during their production can be determined; the main disadvantage of paper capacitor is that they absorb moisture from the atmosphere and reduce the insulation resistance of the dielectric. The dielectric affects it because it absorbs moisture from the atmosphere.

Applications of Paper Capacitor

Electrical and electronic circuits

High voltage and high current applications

Used as a sensor to measure air humidity, fuel level and mechanical stress

Used for car audio systems to add extra power to amplifiers as needed

Used in electronic noise filtering, signal coupling and decoupling systems, remote sensing

Used in signal processing systems such as speakers, dynamic random access memory (DRAM), tuning circuits, radio receivers and analog equalizers

Conclusion

The above is an introduction to paper capacitors. If you want to determine the quality of a capacitor, all you need is a wide-range digital multimeter and any type of capacitor in your device. Connect the multimeter leads to both ends of the capacitor plate. Connect the red lead of the multimeter to the positive plate of the capacitor and the black lead to the negative plate.

If the meter reading starts at zero and gradually increases to infinity, the capacitor is good. Therefore, a capacitor can be checked with a digital and analog multimeter to determine if it is good, bad, open, or short.

Online messageinquiry

- Week of hot material

- Material in short supply seckilling

| model | brand | Quote |

|---|---|---|

| MC33074DR2G | onsemi | |

| CDZVT2R20B | ROHM Semiconductor | |

| BD71847AMWV-E2 | ROHM Semiconductor | |

| RB751G-40T2R | ROHM Semiconductor | |

| TL431ACLPR | Texas Instruments |

| model | brand | To snap up |

|---|---|---|

| ESR03EZPJ151 | ROHM Semiconductor | |

| TPS63050YFFR | Texas Instruments | |

| IPZ40N04S5L4R8ATMA1 | Infineon Technologies | |

| BU33JA2MNVX-CTL | ROHM Semiconductor | |

| BP3621 | ROHM Semiconductor | |

| STM32F429IGT6 | STMicroelectronics |

- Week of ranking

- Month ranking

Qr code of ameya360 official account

Identify TWO-DIMENSIONAL code, you can pay attention to

Please enter the verification code in the image below: