What is a heat sink in the electronic components?

In the world of electronic components, heat sinks play a vital role. As a device specifically designed to dissipate the heat generated by electronic components, the heat sink plays an irreplaceable role in maintaining the stability and reliability of electronic equipment. This article will introduce in detail the definition, classification, role and application of heat sinks in electronic components, and discuss their design principles and maintenance methods.

The definition and function of heat sinkA heat sink is a device used to absorb, conduct, and dissipate heat generated by electronic components. In electronic components, the main functions of the heat sink include:

Heat dissipation: Heat sinks absorb the heat generated by electronic components and dissipate it into the surrounding environment, thereby preventing electronic components from overheating.

Prevent component damage: Overheating is one of the main causes of damage to electronic components. By using a heat sink, we can effectively reduce the operating temperature of electronic components, thereby extending their service life.

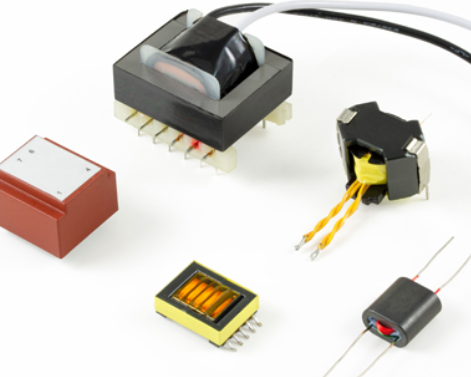

Classification of heat sinksDepending on material, form and function, heat sinks can be divided into the following categories:

Classification according to material: heat sinks can be made of aluminum, copper, steel and other metal materials. Heat sinks made of different materials have different thermal conductivity properties and weight.

Classification according to form: heat sinks can be divided into flat type, fin type, water-cooled type, etc. Flat-plate heat sinks are suitable for low-power electronic components, fin-type heat sinks are suitable for medium to high-power electronic components, and water-cooled heat sinks are suitable for high-power electronic components.

According to functional classification: heat sinks can be divided into passive heat sinks and active heat sinks. Passive heat sinks usually use methods such as increasing surface area and heat transfer media to improve heat dissipation efficiency, while active heat sinks use active driving methods such as fans and heat pipes to improve heat dissipation efficiency.

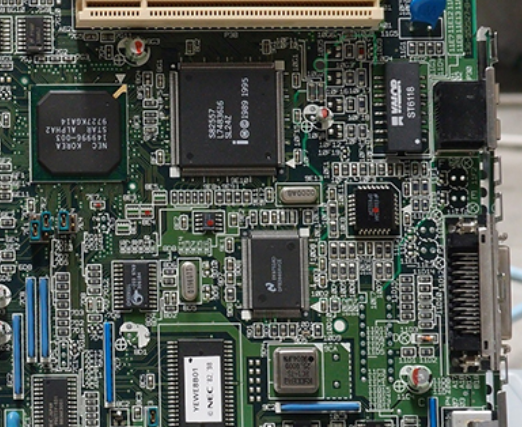

Application of heat sinks in electronic componentsIn electronic components, heat sinks are widely used in various fields. Here are some specific application examples:

Integrated Circuits (ICs): In integrated circuits, a large amount of heat is generated due to the high level of integration and dense transistor layout. In order to ensure the normal operation and stability of the IC, a heat sink is usually required for heat dissipation.

Transistors: Transistors are key components in many electronic devices, and their performance is affected by temperature. By using a heat sink, the operating temperature of the transistor can be reduced, thereby improving its performance and reliability.

Sensors: Many sensors (such as temperature sensors, touch sensors, etc.) require accurate measurement of ambient temperature or pressure. Using a heat sink can help the sensor maintain stable performance, thereby improving measurement accuracy.

Design principles and maintenance methods

Design Principles: When designing and selecting a heat sink, the following factors need to be considered:

(1)- Structure: The appropriate heat sink structure should be selected according to the shape and size of the electronic components.

(2)- Materials: Appropriate materials should be selected according to the power of electronic components and the working environment. For example, aluminum and copper have better thermal conductivity, while steel has higher strength.

(3)- Process: Mature processes should be selected to ensure the quality and reliability of the heat sink.Maintenance methods: To ensure the normal operation of the heat sink and extend its service life, here are some suggestions:

(1)- Regular cleaning: Regularly remove dust and other impurities on the surface of the heat sink to improve its heat dissipation efficiency.

(2)- Check fasteners: Regularly check and tighten the fasteners between the heat sink and electronic components to ensure good heat conduction.

(3)- Replace thermal grease: When the thermal grease is found to be dry or hardened, new thermal grease should be replaced in time to ensure smooth heat conduction.

(4)- Avoid collisions and vibrations: Try to avoid collisions and vibrations to avoid damage to the heat sink and electronic components.ConclusionIn electronic components, heat sinks play a vital role. By absorbing, conducting and dissipating the heat generated by electronic components, heat sinks help maintain the stability and reliability of electronic equipment. This article details the classification, functions and applications of heat sinks, as well as design and maintenance methods. With the continuous development of science and technology, we can foresee that more new and efficient heat dissipation technologies will be used in the field of electronic components in the future.

在线留言询价

- 一周热料

- 紧缺物料秒杀

| 型号 | 品牌 | 询价 |

|---|---|---|

| RB751G-40T2R | ROHM Semiconductor | |

| TL431ACLPR | Texas Instruments | |

| CDZVT2R20B | ROHM Semiconductor | |

| MC33074DR2G | onsemi | |

| BD71847AMWV-E2 | ROHM Semiconductor |

| 型号 | 品牌 | 抢购 |

|---|---|---|

| BP3621 | ROHM Semiconductor | |

| STM32F429IGT6 | STMicroelectronics | |

| ESR03EZPJ151 | ROHM Semiconductor | |

| BU33JA2MNVX-CTL | ROHM Semiconductor | |

| IPZ40N04S5L4R8ATMA1 | Infineon Technologies | |

| TPS63050YFFR | Texas Instruments |

- 周排行榜

- 月排行榜

AMEYA360公众号二维码

识别二维码,即可关注

请输入下方图片中的验证码: