- Ameya360 Component Supply Platform >

- Trade news >

- Advanced Packaging in High Demand, TSMC and OAST Increasing Equipment Orders

Advanced Packaging in High Demand, TSMC and OAST Increasing Equipment Orders

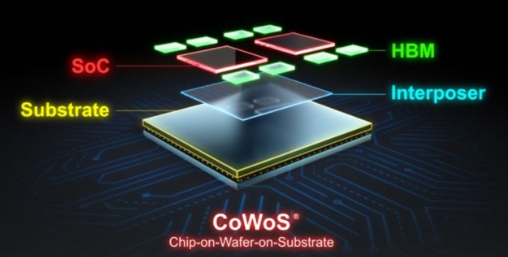

As AI demand continues to surge, TSMC (Taiwan Semiconductor Manufacturing Company) has initiated an extensive expansion plan for its CoWoS (Chip-on-Wafer-on-Substrate) production. Within the industry, reports suggest that TSMC, a leading semiconductor foundry, placed a significant wave of orders with Taiwanese equipment manufacturers last week, creating a notable impact.

Additionally, outsourced semiconductor assembly and testing (OSAT) giants, which were originally inquiring about orders, have also significantly increased their orders for advanced packaging. This wave of orders is estimated to be fulfilled between March and April of the upcoming year.

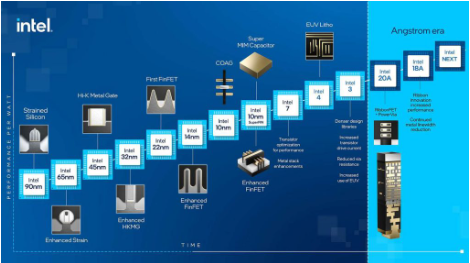

The growth in demand for advanced semiconductor processes due to AI applications necessitates advanced packaging technologies to keep pace. With packaging technologies advancing from 2D and 2.5D to the more advanced 3D IC (Integrated Circuit) configurations, the number of IC stacking layers is increasing, leading to a greater demand for advanced packaging equipment. Considering the current emphasis on CoWoS technology, the industry estimates that production capacity will reach 12,000 to 14,000 wafers in 2023 and double to over 30,000 wafers in 2024.

According to a report by Taiwan’s Money DJ, information from equipment industry sources reveals that TSMC recommenced orders for CoWoS equipment in April 2023, with a second wave of orders in June. Subsequently, sporadic additional orders were placed, and last week witnessed a new significant wave of orders, surprising many.

An anonymous executive from a Taiwanese equipment company expressed that they initially believed TSMC’s orders for CoWoS equipment had concluded, making the recent wave of orders even more unexpected. Furthermore, the increase in orders for advanced packaging equipment by semiconductor testing and packaging facilities is also seen as encouraging.

Market experts believe that semiconductor testing and packaging facilities and semiconductor foundries have different positions and advantages in the advanced packaging market. Their cooperative relationships outweigh their competition. Major OSAT players like ASE, Amkor, and JCET have long possessed advanced packaging technology and are positioned to become an alternative choice for major foundries due to their technical upgrades and competitive pricing. In other words, top-tier orders from customers will be firmly in TSMC’s grasp, while other opportunities will likely be pursued by SATS companies.

Regarding the supply of CoWoS equipment, suppliers like Scientech have received over 30 orders for wet etching processing equipment, while Grand Process Technology and others have shipped nearly 20 units. Meanwhile, G2C+ Alliance members such as GMM and C Sun have reportedly received over 40 orders from the TSMC’s Longtan factory.

Online messageinquiry

TSMC Expected to Lower Capital Expenditure, Potentially Falling Below $30 Billion for the Year

- Week of hot material

- Material in short supply seckilling

| model | brand | Quote |

|---|---|---|

| RB751G-40T2R | ROHM Semiconductor | |

| MC33074DR2G | onsemi | |

| CDZVT2R20B | ROHM Semiconductor | |

| TL431ACLPR | Texas Instruments | |

| BD71847AMWV-E2 | ROHM Semiconductor |

| model | brand | To snap up |

|---|---|---|

| BP3621 | ROHM Semiconductor | |

| BU33JA2MNVX-CTL | ROHM Semiconductor | |

| ESR03EZPJ151 | ROHM Semiconductor | |

| STM32F429IGT6 | STMicroelectronics | |

| TPS63050YFFR | Texas Instruments | |

| IPZ40N04S5L4R8ATMA1 | Infineon Technologies |

- Week of ranking

- Month ranking

Qr code of ameya360 official account

Identify TWO-DIMENSIONAL code, you can pay attention to

Please enter the verification code in the image below: