- Ameya360 Component Supply Platform >

- Trade news >

- What is the difference between thick film and thin film circuit board?

What is the difference between thick film and thin film circuit board?

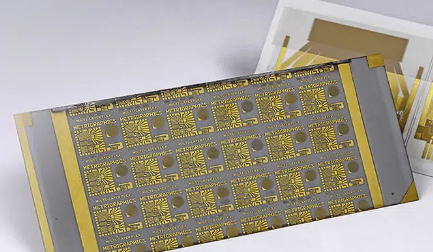

Thin film circuit boards are specialized substrates used in electronic applications where precision, miniaturization, and high performance are crucial. They’re constructed by depositing thin layers of conductive, resistive, or insulating materials onto a substrate, typically made of ceramic or glass.

What is a thick film circuit board?A thick film circuit board refers to a type of printed circuit board (PCB) that utilizes thick film technology in its manufacturing process. In contrast to traditional thin film PCBs, which use thin layers of conductive material deposited on the board, thick film circuit boards involve the deposition of thicker layers of conductive and resistive materials on the board’s surface.

The manufacturing process involves screen printing a paste-like mixture of conductive materials, such as silver, gold, or palladium, along with glass or ceramic materials, onto the substrate. This thick film paste is then fired at high temperatures to fuse the materials onto the board, forming the conductive traces, resistors, and other circuit elements.Thick film circuit boards offer several advantages:

Cost-Effectiveness: The manufacturing process is generally less expensive compared to traditional thin film technologies.

Ease of Prototyping: Thick film technology allows for rapid prototyping and quick modifications to circuit designs.

Adaptability: They are suitable for hybrid circuits, combining both passive and active components on the same substrate.

Robustness: Thick film boards tend to be more durable and resistant to environmental factors like moisture and temperature variations.

These boards find applications in various industries, including automotive electronics, industrial controls, sensors, and certain medical devices where cost-effective and robust circuitry is required.

What is a thin film circuit board used for?Thin film circuit boards are primarily used in applications where high precision, high-frequency, and high-performance electronic circuits are necessary. These boards are manufactured by depositing thin layers of conductive materials, typically metals like gold, platinum, or alloys, onto a substrate using specialized deposition techniques such as sputtering or chemical vapor deposition.

Some common applications of thin film circuit boards include:

High-Frequency Electronics: Thin film boards excel in high-frequency applications such as microwave devices, satellite communication systems, and radar systems due to their low signal loss and high-frequency capabilities.

Aerospace and Defense: These boards are extensively used in aerospace and defense applications where reliability, miniaturization, and high performance are critical, including in avionics, navigation systems, and military-grade electronics.

Telecommunications: Thin film technology is employed in telecommunications equipment where high-speed data transmission and signal integrity are essential, such as in network infrastructure and data centers.

Medical Devices: Certain medical devices, especially those requiring precise sensors or high-frequency components, use thin film circuitry for their compactness and reliability, such as in medical imaging devices or diagnostic equipment.

Optoelectronics: Thin film boards are used in optoelectronic devices like LEDs, photodetectors, and fiber optics due to their compatibility with optical materials and precise fabrication requirements.

Consumer Electronics: In some specialized consumer electronics requiring high performance, like certain types of audio equipment or high-speed data processing devices, thin film technology might be employed.

These applications benefit from the thin film’s precise deposition, allowing for highly accurate and controlled circuit elements, low noise, excellent signal integrity, and the ability to operate at high frequencies.

What is the difference between thick film and thin film circuit board?The difference between thick film and thin film circuit boards primarily lies in their manufacturing processes, material thickness, and applications:

Manufacturing Process:

Thick Film: Thick film circuit boards are manufactured by depositing relatively thicker layers of conductive materials (usually pastes containing metal oxides) onto a substrate through screen printing or stencil printing processes. These layers are then fired or cured to create the circuitry.

Thin Film: Thin film circuit boards are made by depositing very thin layers of conductive materials (typically metals like gold, platinum, or alloys) onto a substrate using advanced deposition techniques such as sputtering or chemical vapor deposition.

Material Thickness:

Thick Film: The conductive and insulating layers in thick film circuits are relatively thicker, often in the range of several micrometers to tens of micrometers.

Thin Film: In contrast, thin film circuits have extremely thin conductive layers, typically in the range of a few nanometers to a few micrometers.

Applications:

Thick Film: Thick film circuits are commonly used in applications where cost-effectiveness, robustness, and moderate precision are required. They find use in automotive electronics, household appliances, sensors, and some medical devices.

Thin Film: Thin film circuits excel in applications that demand high precision, high frequency, low noise, and superior performance. They are used in high-frequency communication systems, aerospace technology, defense applications, and high-end electronic devices where miniaturization and precision are critical.

Performance:

Thick Film: These circuits typically have higher resistance and lower precision compared to thin film circuits.

Thin Film: Thin film circuits offer higher precision, low signal loss, excellent high-frequency performance, and are capable of handling high-speed data transmission due to their minimal thickness and precise fabrication.

In summary, thick film and thin film circuit boards differ in their manufacturing techniques, material thickness, and the applications they are best suited for.

Online messageinquiry

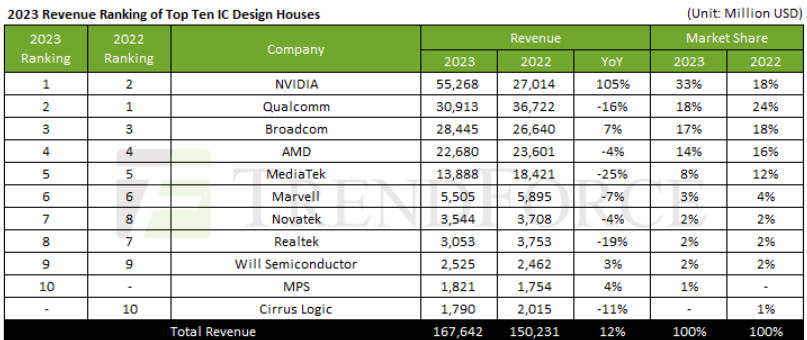

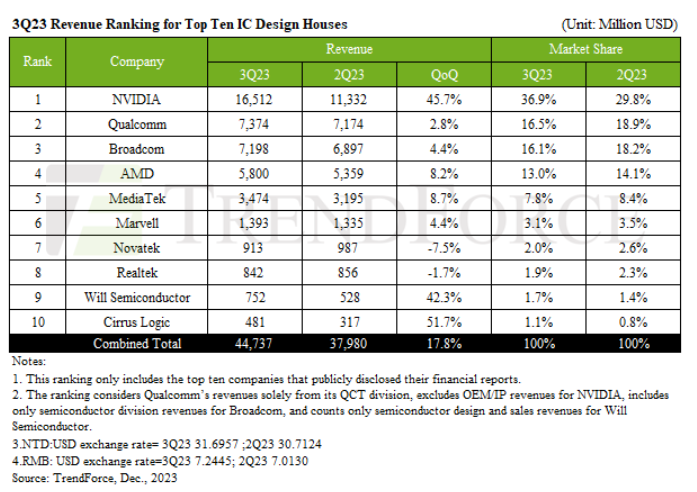

Unveiling the Intricacies of IC Design

- Week of hot material

- Material in short supply seckilling

| model | brand | Quote |

|---|---|---|

| TL431ACLPR | Texas Instruments | |

| MC33074DR2G | onsemi | |

| BD71847AMWV-E2 | ROHM Semiconductor | |

| CDZVT2R20B | ROHM Semiconductor | |

| RB751G-40T2R | ROHM Semiconductor |

| model | brand | To snap up |

|---|---|---|

| IPZ40N04S5L4R8ATMA1 | Infineon Technologies | |

| STM32F429IGT6 | STMicroelectronics | |

| ESR03EZPJ151 | ROHM Semiconductor | |

| BU33JA2MNVX-CTL | ROHM Semiconductor | |

| TPS63050YFFR | Texas Instruments | |

| BP3621 | ROHM Semiconductor |

- Week of ranking

- Month ranking

Qr code of ameya360 official account

Identify TWO-DIMENSIONAL code, you can pay attention to

Please enter the verification code in the image below: